The welding of aluminium and its alloys

Distortion

Residual stress due to heating and cooling of the HAZs and the contraction of the weld metal as it cools from a molten state to ambient temperature is an unavoidable feature of welded joints. The stress deriving from this shrinkage results in distortion. This distortion may be localised, evenly distributed and acceptable or may render the entire structure unfit for its purpose. In a ship’s hull, for instance, buckling of the hull plates can induce turbulence and increase drag; in piping it can restrict fluid flow; and in architectural applications it can be aesthetically unacceptable.

|

|

|

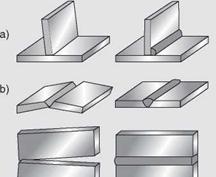

Transverse and longitudinal shrinkage in a butt weld |

|

Angular distortion from fillet welds |

|

Bowing in a plate due to longitudinal shrinkage |

|

Result of angular distortion caused by fillet welded longitudinal stiffeners |

|

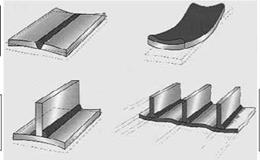

5.18 Longitudinal, transverse and angular distortion. Courtesy of TWI Ltd. |

|

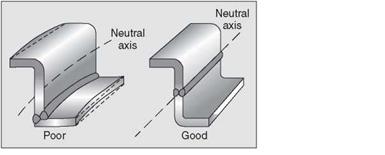

5.19 Welding around the neutral axis. Courtesy of TWI Ltd. |

Distortion can appear as longitudinal shrinkage, transverse shrinkage, angular distortion, bowing or buckling. The various forms are shown in Fig. 5.18. The amount of distortion is affected by the heat input from the welding process, the welding sequence, joint design, the amount the joint is restrained, stresses in the parent metal and its physical characteristics.

Although the coefficient of thermal expansion of aluminium is about twice that of steel, its high thermal conductivity means that temperature gradients are less severe. However, the change that occurs when the weld metal solidifies is around a 5% volume shrinkage, compared with a 3% reduction in steel. The net result is that distortion in aluminium is somewhat greater than would be expected in a similar steel structure. If the metal is in a highly stressed state, such as being cold worked, this will also lead to greater distortion as these stresses are released by the heat of welding.

The measures that can be taken to minimise the problem are similar to those that would be used for steel:

• Weld on or very close to the neutral axis.

• Balance the welds about the neutral axis of the component (Fig. 5.19).

|

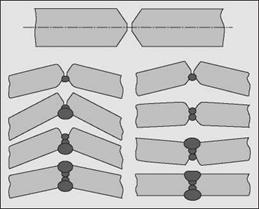

5.20 Balanced welding in a butt weld. Courtesy of TWI Ltd. |

• Where appropriate use a double-V preparation and balance the welding about the plate centre line (Fig. 5.20).

• Use the lowest heat input process and welding parameters, consistent with achieving the required quality. Of the fusion welding processes the power beam processes - electron beam or laser welding - will give the least distortion.

• Use the fewest number of weld passes to fill the joint. This implies that a high heat input process will result in less distortion than a low heat input process. This may seem to be in conflict with the point above but it should be remembered that it is the total heat input to the joint that is significant. The sum of heat inputs from a large number of small passes will result in a higher total heat input than that from a small number of large beads for the same volume of weld metal. TIG welding, for instance, will almost always give more distortion than MIG welding the same component.

• On long welds, weld from the centre towards the ends. On items such as beams this will approximately halve the amount of bowing that would be expected if the beam was welded by starting at one end and welding through to the opposite end.

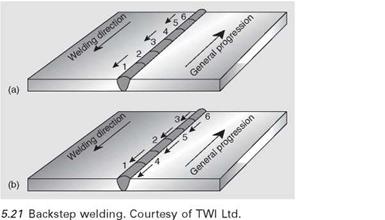

• Use a ‘back-step’ sequence, i. e. weld from a cold section of joint towards a hot section already welded (Fig. 5.21).

• Break the construction down into sub-assemblies, weld the individual sub-assemblies and assemble the complete item, balancing any distortion from the individual items to minimise the overall distortion.

• Preset the components (Fig. 5.22). If the amount of distortion is known or can be predicted, the items can be assembled and offset by the amount of expected distortion. On completion of welding the distortion

|

|

|

c) 5.22 Presetting of components before welding. Courtesy of TWI Ltd. |

has been used to pull the items to within tolerance. This technique is most easily used to cope with angular distortion on plates.

• Use automatic welding. This may enable faster travel speeds to be used and hence lower heat input to be achieved. Mechanised/automatic welding will also give more consistent distortion which enables the technique of pre-setting components to be used with greater confidence.

• Use a planned welding sequence. This is of use on fabrications such as lattice beams where a planned sequence can be of great benefit. The precise sequence to minimise distortion will vary from assembly to assembly and is best designed from experience. Staggered welds, back step and skip welding can also be employed.

• Use adequate tack welds. In a butt joint the contraction of the solidifying weld metal tends to pull together the two edges (Fig. 5.22).With thin

|

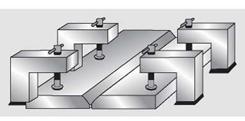

5.23 Jigging of plate to maintain flatness. Courtesy of TWI Ltd. |

sheets this can result in the edges riding up over each other, requiring the tack welds to be more closely pitched. The length of tack welds should be in the region of 8 times the component thickness and spaced at intervals not greater than 35 times the thickness. They must be made with the same procedure and with as much care as the main weld. Tacks are expected to carry the assembly stresses and can therefore experience high loads that may well cause cracking problems. Incorporation of cracked tacks in the constructional weld will be an expensive problem to eliminate!

• Ensure that the joint fit-up is accurate. This is perhaps one aspect where the importance cannot be over-emphasised. Large root gaps, for instance, will always result in large amounts of distortion as the root weld metal contracts.

• Do not over-weld and avoid the use of wide bevel angles, large root gaps and large amounts of excess metal. Fillet welds should be as small as permitted by design - for example, an 8 mm leg length fillet weld contains over 80% more weld metal than a 6 mm leg length fillet. It is worth remembering that not only does excess weld metal increase distortion, it also costs a lot of money to deposit it!

• Use jigs and fixtures (Fig. 5.23), to hold and retain the components in the correct alignment. The use of rigid restraints will give increased levels of residual stress and may increase the risk of cracking. Jigs need to be designed to provide good access for welding, to be rigid and robust, to be foolproof in use and to be well maintained to ensure that wear is taken into account and tolerances are achieved.