New developments in advanced welding

Tubular cored wire welding

2.1 Introduction: process principles

Tubular cored wire welding was foreseen in the 1911 patent application1 in which Oscar Kjellberg introduced the world to the concept of the coated welding electrode: as an alternative, he said, a tube could be used with the powder or paste inside. By 1936, 10000 tonnes of tubular electrodes had been produced in Austria and the Schlachthof Bridge in Dresden had been fabricated by mechanised welding with tubular wire.2 This advanced welding process thus has a rather longer history than some of the others described in this book. However, it was only in the last part of the twentieth century that competitive pressures spurred on the rapid expansion in its use that led to its important position today.

Tubular wires were developed to bring together the advantages of two existing processes. Manual metal-arc (MMA) electrodes have a coating which can alloy and deoxidise the weld, form a slag to protect, refine and support the pool, and contribute ionic species to stabilise and modify the arc. Gas - shielded metal-arc welding (GMAW) was introduced in the 1920s to allow continuous welding with its inherently greater productivity, but was limited, especially in positional welding, by its lack of slag. Tubular wires use in many cases the same welding equipment as solid wires but have a number of advantages in usability, productivity and metallurgical flexibility.

At this point it may be useful to clarify the terminology of tubular wires. Many of these are widely known as flux-cored wires, and the American Welding Society refers to ‘flux-cored arc welding’. In the 1950s, a range of wires appeared containing no fluxing agents, but only metal powders: these became known as metal-cored wires. In American standards they are regarded as a subset of solid wires. However, British patents on metal-cored wires allowed for the inclusion of non-metallic elements in the core up to a total of 4% by weight,3 and the European approach has been to see a continuum between metal-cored and flux-cored wires. Hence the term ‘tubular wires’ has been adopted in British and subsequently European and ISO standards.

|

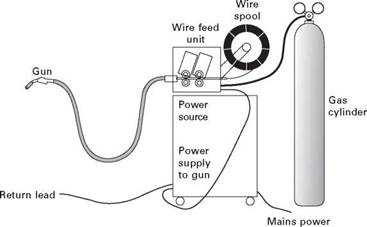

2Л Equipment used for welding with tubular wire. |

In operation, as seen in Fig. 2.1, a wire is fed from a spool through a conduit to a torch or gun, which may be hand-held or mounted on a mechanical traverse. The wire passes through a contact tip by means of which current is supplied to the wire, and which may be surrounded by a cylindrical gas nozzle or shroud if the wire is of a type that calls for gas shielding. As in gas - shielded welding with solid wire, the power source normally supplies an almost constant voltage so that the arc is self-stabilising. If, for example, the arc starts to shorten, its impedance is reduced. If the impedance of the power source is still lower, in other words if it is of the constant voltage type, coupling between the power source and the arc will increase and the wire will burn off faster until equilibrium is restored.

Users of gas-shielded welding with solid wire will be familiar with the different operating modes of the process as the wire feed speed and voltage vary. When both of these are high, fine droplets stream from the wire tip in what is known as ‘spray transfer’, so current and voltage remain relatively constant over both short and long time scales. At low voltages and currents, however, the arc power is not enough to burn off the wire as fast as it is feeding. The wire tip will approach the molten pool and eventually a short circuit will occur. Because of the sudden improvement in impedance matching, the power transfer increases and soon melts the wire tip. The molten bridge breaks, the arc is re-established and the process repeats itself. This is known as ‘dip transfer’. Because the total power absorbed is less and the weld pool smaller, this transfer mode is preferred for positional welding.

In principle, similar transfer modes can be observed with tubular wires, albeit not always in such a pure form. Metal-cored wires can behave very like solid wires, with a transition from dip to spray. Basic flux-cored wires certainly have a short-circuiting transfer mode, but at higher currents the droplets rarely become fine enough for the transfer to be classified as true spray, even though it may appear as such to the welder. Rutile flux-cored wires, on the other hand, produce free-flight transfer over their whole operating range and do not rely on a short-circuiting mode for positional welding. These characteristics are dealt with in more detail in Section 2.4 below.

Power sources were originally transformer-rectifier machines, later with thyristor control, but many today make use of inverters to allow the power transformer to operate at a higher frequency and thus be reduced in size. A further benefit is that the static and dynamic characteristics of the power source can be controlled more accurately and over a wider range using a microprocessor, so that the output can be optimised for each type of wire, and indeed often for covered electrodes as well. For tubular wires, operating voltages of 15-35V may be needed. Unlike solid wires, some tubular wires are designed to operate with electrode negative and so may not be suitable for some older equipment which does not provide for this.

With a modern inverter set, it is often possible to provide a pulsed arc facility at little or no extra cost, and this can be helpful to reduce spatter when using basic flux-cored wires. Because the electrical and arc characteristics of tubular wires vary much more than those of solid wires, some experience may be needed to optimise the pulse parameters for any given type. Some manufacturers therefore pre-program their power sources so that the appropriate wire type can be selected from a menu.

In the past, wire feeders were often the Achilles’ heel of equipment for welding with tubular wire. Feeders designed for solid wire have smooth drive rolls, one of each pair being grooved to provide the wedging action which generates the frictional force for feeding. High pressures are unlikely to damage the wire. The major cause of feeding problems with tubular wire was over-tightening of the drive rolls. This, especially with early wires which were often softer than today’s, could squash the wire, increasing the risk of buckling and allowing powder to escape from the seam and clog the conduit liner. Modern feeders often have twin drive rolls to increase the tractive effort without increasing the pressure on the wire. For optimum efficiency, the pairs of rolls should either be independently driven or should be linked by differential gearing to prevent slip caused by production tolerances on roll geometries.

For wires of more than 1.2 mm diameter, knurled rolls are often used. Particular care is again needed not to tighten the rolls so much that they damage the wire surface, causing it in turn to wear the contact tip unnecessarily quickly.

24 New developments in advanced welding

When tubular wires were first reintroduced in the 1950s, they were competing chiefly with manual metal-arc electrodes and before even considering deposition rates, the increased duty cycle of a continuous process was a major benefit. The first tubular wires thus replaced stick electrodes, although small diameter wires were not at first available and only downhand welding was possible. Later, the GMAW process with solid wires was widely promoted and the cost of the wires fell, especially in Europe. Users converted from MMA to GMAW and a more sophisticated case then had to be made for tubular wires.

The widespread acceptance, in Europe at least, of tubular wires was not helped by a misunderstanding by those promoting their use of where their real benefits lay. A fact easily grasped by marketing departments was that at a given current, a tubular wire will generally deposit metal at a faster rate than a solid wire of the same diameter. This is because almost no current is carried by the core of a tubular wire, even in the case of metal-cored wires. The smaller cross-section of the current-carrying sheath leads to more resistive heating in the electrode extension and a faster burn-off rate. Fabricators were often ahead of salesmen in realising that this is not unambiguously beneficial.

There is no reason why consumables should be compared at a fixed current, unless this is limited by the welding equipment. The current used in a particular application should be determined by the productivity required, the properties of the weld metal and heat-affected zone, and the geometry and appearance of the weld bead. Flux-cored wires have been used in semi-automatic applications at 600 A: in such cases, the use of a wire designed for CO2 shielding reduced the radiation and ozone levels which would have made the use of a solid wire unpleasant, and a rather stiff slag maintained a good fillet weld profile. The same 2.4 mm wire has been used in a mechanised application at 900A, depositing about 19kg/h of weld metal.

In recent years, among the largest users of tubular wires have been shipyards. Here, metal-cored wires have been used in place of solid wires for the fillet welding of stiffeners and box sections. While similar deposition rates have been claimed for solid wires used at very high current densities, the driving force for the use of the more expensive tubular wires has been the good penetration, underbead shape and surface profile of the welds, resulting in very low defect levels. Paint manufacturers and welding consumable manufacturers working together have also been able to develop combinations of prefabrication primers and tubular wires that minimise problems when welding over primer.

In offshore construction, rutile tubular wires are used in positional welding at deposition rates much higher than those of either covered electrodes or GMAW with solid wire. Here, the slag is stiff enough to allow welding uphill in a free-flight transfer mode at currents up to 250A, giving deposition rates above 4kg/h. At the same time, metallurgical control which would not be possible with a solid wire ensures the required combination of strength and toughness.

In Europe, tubular wires still only constitute about 10% of total welding consumable consumption, while in Japan and North America the percentage is 35 or more.4 In a Korean shipyard, the use of tubular wires is quoted as 94 % of the total. It has at times seemed that the adoption of tubular wire in Europe was fuelled more by the knowledge of what international competitors were doing than by a thorough understanding of process costs and benefits. However, in all markets the proportion of welding using tubular wires is foreseen to rise in the immediate future,4 and that consensus is a good indication that the potential of the process is no longer in doubt.