New developments in advanced welding

Nd:YAG laser welding

M. NAEEM, GSI Group, UK and M. BRANDT, Swinburne University of Technology, Australia

Nd:YAG lasers have been commercially available for over 30 years. The Nd:YAG (neodynium doped yttrium aluminium garnet) crystals in these lasers can be pumped either using white light flashlamps or, more efficiently, using laser diodes. The Nd:YAG laser is one of the most versatile laser sources used in materials processing. The relative robustness and compactness of the laser and the possibility for the 1.06 mm light it produces to be transmitted to the workpiece via silica optical fibres are two features which contribute to its success. Nd:YAG lasers when first commercialised operated mainly in pulsed mode, where the high peak powers which can be generated were found useful in applications such as drilling, cutting and marking. These pulsed lasers can also be utilised for welding a range of materials. More recently, high power (up to 10kW), continuous wave (CW) Nd:YAG lasers have become available.

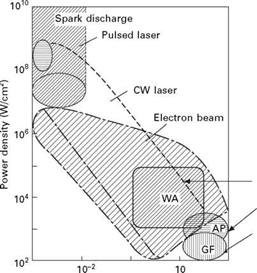

Because of the wide range of applied power and power densities available from Nd:YAG lasers, different welding methods are possible. If the laser is in pulsed mode and if the surface temperature is below the boiling point, heat transport is predominantly by conduction and a conduction limited weld is produced. If the applied power is higher, for a given speed, boiling begins in the weld pool and a deep penetration weld can be formed. Figure 5.11 shows the power densities, in W/cm2, for various laser processes. Pulsed Nd:YAG lasers provide higher power density than any other available source.

5.2 Laser output characteristics

Nd:YAG lasers are characterised by the their power output over time i. e. pulsed, CW and supermodulated (a feature exclusive to GSI Lumonics’ new JK continuous wave products).2

|

|

|

GF: gas flame |

|

WA: welding arc |

|

AP: arc plasma |

|

Hot spot diameter (cm) 5.1 Power densities for different welding processes. |

Pulsed Nd:YAG lasers employ a power supply designed for delivering high peak powers during the laser pulse and do not have CW capability. Pulsing implies that the laser’s active medium is excited by a very quick response stimulus. This allows the laser to transmit a burst of energy for a brief length of time (generally in terms of milliseconds). Peak pulse powers for pulsing Nd:YAG lasers can reach values of over 30 times greater than the maximum average power levels. This allows low-to-medium power lasers to achieve enough energy to reach vaporisation temperatures for most materials.

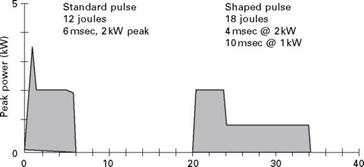

The basic laser pulse from the pulsed laser is a rectangular pulse with an initial overshoot spike as shown in Fig. 5.2. Often the single sector standard pulse is quite adequate when welding standard ferrous alloys without a coating or carrying out standard pulsed YAG cutting applications. However, with most welding reflective or dissimilar materials, pulse shaping has a measurable effect on the quality and consistency.3 Most lasers are rated by their CW output, but pulsed lasers have pulsed energy, peak power, pulse width and frequency terminology that must be understood.

Pulse energy

The volume of the melt puddle for each pulse is determined by the pulse energy. There is a minimum pulse energy required for weld penetration to a

|

Time (msec) 5.2 Basic laser pulse with an initial spike and shaped pulse. |

certain weld depth for a given material. Energy per pulse in joules (E) is related to the average power in watts (P) and the pulse frequency (f) by the following:

E(J) = P (W)/f (Hz) [5.1]

Peak power

Height of the pulse is the peak power as shown in Fig. 5.2 and this peak power breaks down reflectivity and overcomes thermal diffusivity. The high peak power is required for precious metal welding and for a range of aluminium alloys. The peak power (Pp) can be calculated by the following:

Pp(kW) = E(J)/t(s) [5.2]

Pulse frequency and overlap

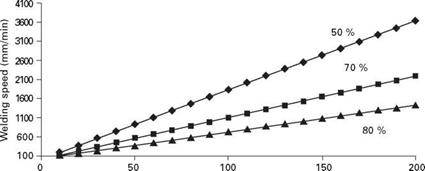

During pulsed Nd:YAG welding, seam welds are produced by a series of spot welds. The pulsing rate of the laser results in faster or slower seam welding as the rate is increased or decreased. To produce hermetic welds, pulse rate ( f), spot diameter (d) and the weld speed (v) have to be matched to produce the required percent overlap (%OL). Generally speaking typical values for hermetic welds are between 70 and 80%OL and for non-hermetic welds between 50 and 60 % OL. The percent overlap can be calculated by the following:

%OL = 100[(d - v/f )/d] [5.3]

Figure 5.3 shows relationship between welding speed and frequency for three different percent overlaps.

|

Pulse frequency (Hz) 5.3 Welding speed vs. repetition rate for different percent overlaps (spot size 0.60mm). |

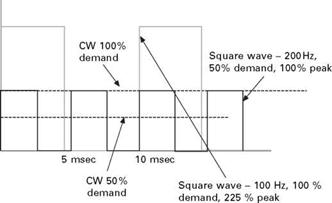

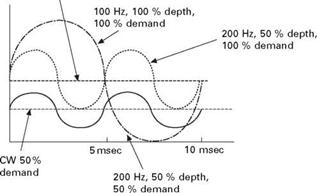

Continuous wave (CW) Nd:YAG lasers produce a constant output power without interruption and can usually be varied from about 10% to 100% of their mean power rating. GSI Lumonics’ proprietary super modulation (SM) technique involves storing some energy in the laser’s power supply during the off time of the laser or when the laser is operating below its rated power, and then quickly sending this stored energy to the laser’s lamps for extra bursts of peak power. The peak power attainable can be as much as 200 % of the laser’s mean power. In this way, a supermodulated laser can operate at CW just like any other but can also be directed to produce a square wave, sine wave, or other repetitive output with peak powers above the mean power rating while also producing full mean power. For example, in a 50% duty cycle square wave output, the laser will produce 200% of the CW rating during the laser’s pulse ‘on-time’, thereby producing an average output equal to the laser’s full rating. Typical laser outputs are shown in Fig. 5.4. The momentary increase in peak power provided by supermodulation produces some exceptional results during welding (see later sections).

• Minimum heat input: Pulsed Nd:YAG is the choice. If components have metallurgical constraints on heat input or there are heat-sensitive components nearby such as glass-to-metal seals or o-rings, the pulsed YAG can be set up to achieve the required processing rate at a heat input low enough not to damage the components.

• Speed: CW Nd:YAG is the best choice. Whether cutting or welding, by processing the component with a CW beam there is no need to overlap

pulses or to re-establish the keyhole. Simply adjust power and speed along with the focus spot size to achieve the desired penetration.

|

CW 100% demand |

|

5.4 CW output vs. square and sine wave supermodulation waveforms. |

• Welding reflective materials: Usually pulsed Nd:YAGs. For copper and precious metals the pulsed Nd:YAG has the peak power to break down the reflectivity. Only very high average power CW Nd:YAGs can process these materials.

• Heat treating/cladding: Usually CW Nd:YAGs. Average power tends to be the limit to speed, case depth, or remelt thickness. Pulsed Nd:YAGs can do the job but their lower average power ratings rule them out except for small devices.

• Spot welding: Usually pulsed Nd:YAGs. By setting the pulse parameters correctly, the pulsed laser is the fastest and most repeatable spot welder. Only if large diameter nuggets are required would a CW laser be considered.

• Low penetration welding: CW laser will weld very quickly and produce parts with high throughput. Pulsed lasers might have sufficient speed also and have the benefit of dealing with material changes or spot welding requirements.

• Welding crack-sensitive alloys: CW Nd:YAG is the best choice unless there are other constraints such as heat input. The slower cooling rate of the CW laser usually reduces cracking tendencies. This is true of steel alloys containing sulphur, phosphorus, lead, and/or selenium. Also for welding mild steel to stainless steel or steels with poor Cr: Ni equivalent ratios.