Development of new system testing facilities

Different SDHW systems (thermosiphon systems, integrated collector-storage systems and forced - circulation systems) have been tested at Fraunhofer ISE since 1997 The testing facilities for preassembled systems have now been expanded to satisfy the growing demand of these tests according to the European testing standard EN 12976. From now on it is possible to perform up to four tests of SDHW systems at the same time. Furthermore, it will be possible to carry out tests of heat storage tanks.

SDHW systems are tested for the Solar Keymark certification according EN 12976-1,2. This includes an efficiency test on the system, functional tests on the system and functional tests on the collector applied in the system. The tests will be briefly described in the following.

Efficiency test

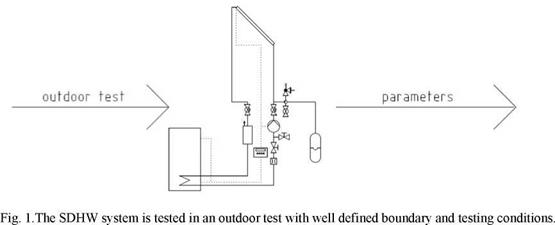

The parameters of the systems are experimentally determined by an outdoor test with a number of testing days. The boundary conditions like daily irradiation, ambient temperature and cold water inlet temperature for a testing day to be valid are defined in the testing standard.

A simulation is carried out using the parameters which were determined in the efficiency test. The performance prediction simulations are carried out for different reference locations (Wurzburg, Stockholm, Davos and Athens are the standard locations but the calculations can be carried out also for other locations.).

|

|

|

Fig. 2.The parameters determined in the outdoor test are used for a prediction of the system output for reference locations in Europe. |

Functional tests on the system

• Freeze resistance

The aim of the freeze resistance test is to check whether the necessary precautions have been taken to protect the system from temperatures below zero.

• Pressure resistance

Within the pressure resistance tests all circuits are checked on their ability to hold and withstand pressure.

Ability of the solar-plus-supplementary-system to cover the load

The intention of this test is to assess the ability of the system to provide the maximum daily load on days without contribution out of the solar loop.

• Over temperature protection

The test is done to make sure that the system is able to withstand a period of high solar radiation without hot water drawn from the tank. The intention is also to make sure that no dangerous situations occur for the user.

О

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

О D.

О D.

Fig. 3. Measurements of an over temperature test. The graph shows the irradiance, the power consumption of

the pump in the collector loop and the outlet temperature of the collector array (as mean values averaged

over five minutes). By means of the controller of the system the pump is operated intermittingly in order to

prevent the collector from overheating. The storage tank is cooled by the collector (it is a selective flat plate

collector in this case) until a certain threshold temperature is reached. The test showed that the risk of a

stagnation phase with evaporation of the fluid in the collector loop is reduced sufficiently..

Functional tests on the collector

Additional functional tests are performed on the collector of the system unless a complete test according EN 12975 has been performed already. The tests include:

• Exposure test

• High-temperature resistance test

• External thermal shock tests (twice)

• Internal thermal shock tests (twice)

• Rain penetration test

• Stagnation temperature

• Mechanical load test

• Final inspection