Optimum Operating Point

There are a number of different criteria that are frequently quoted for gasification processes (Reimert 1989). The two most commonly encountered are cold gas efficiency (CGE) and carbon conversion. The definitions are:

![image019 Подпись: Cold gas efficiency [%]](/img/1165/image019.gif)

|

Heating value in product gas [MW] x ^qq Heating value in feedstock [MW]

whereby it is important always to clarify whether the heating values are on a higher heating value (HHV) or lower heating value (LHV) basis.

Carbon conversion is defined as:

Despite the frequency with which these figures are quoted for different gasification systems, care is required with their interpretation, since both only provide a limited statement about the process efficiencies and gas quality. A process that produces a gas with a relatively high methane content and therefore has a high cold gas efficiency will be good in a power application, but it may not be the optimum choice for a synthesis gas application, in which case the H2 + CO yield will provide a better guide to process selection.

The reason why it can be advantageous to gasify coal in power plants is twofold: for efficiency reasons and environmental reasons.

The efficiency advantage is attributed to the fact that use can be made of the more advanced combined cycle where gas is fired in a gas turbine (Brayton or Joule cycle) and the hot gases leaving the turbine are used to raise steam for a conventional steam (Rankine) cycle. The alternative is firing coal in a conventional steam plant using only a Rankine cycle. The efficiency for gas firing in a state-of-the-art combined cycle is about 58%, a figure that has to be multiplied with the gasification efficiency of, for example, 80%, resulting in an overall efficiency of 46.4%, whereas the efficiency of coal firing in a conventional state-of-the-art steam plant is about 45%. A simple calculation shows that the CGE has to be above 78% in order to make gasification attractive in terms of overall process efficiency. This is all that we will say at this point as it is sufficient in the context of optimization. More will follow in Section 7.3.

The environmental advantage of gasification-based power stations has always been used as an important argument in their favor based mainly on the fact that in the past the sulfur compounds in the fuel gas could be removed with a higher efficiency than from flue gases from conventional coal or heavy oil fired power stations. Moreover, there was much optimism that high-temperature sulfur removal would be possible, which would enhance the efficiency of the IGCC. As will be explained in Section 7.3, there is a case to be made for reconsidering flue gas treating for IGCC, as many more compounds have to be removed apart from sulfur. Furthermore, the efficiency of flue gas desulphurization has improved considerably over the last twenty years. However, one has to accept that environmental arguments are a permanently moving target, since the recent discussion of C02 capture and sequestration may provide a new advantage for fuel-gas treating. This is, however, still dependent on politics.

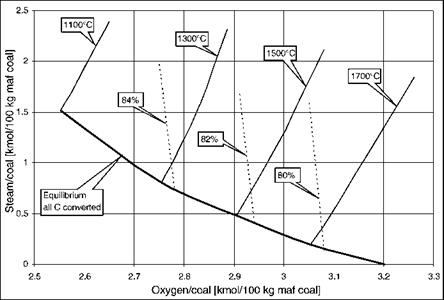

For fuel gas applications the gasification temperature has to be as low as possible, as this will result in the highest CGE (and in the lowest oxygen consumption). In Figure 2-7 iso-CGE lines have been drawn that clearly illustrate this point, as the isotherms run essentially parallel to the iso-CGE lines. Although fluxing may help to enlarge the operating window for certain coals, as will be discussed in Section 5.3, the minimum temperature will always be determined by the reactivity of the coal and the ash-melting characteristics in slagging gasifiers.

In general, temperatures of below 1400°C for low-rank coals and below 1500°C for high-rank coals are impractical. As the data in Figure 2-7 show, the operation

|

Figure 2-7. Cold Gas Efficiencies |

|

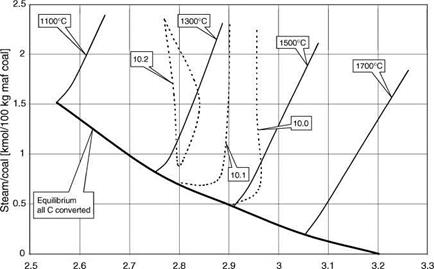

Oxygen/coal [kmol/100 kg maf coal] Figure 2-8. Syngas (H2+C0) Yields for Coal |

should be as close to the thermodynamic equilibrium line for the heterogeneous reaction as is practically possible.