Flexibility of the new testing facility for air-collectors

The components and measurement devices of an air-collector testing loop are more voluminous than for water-collectors. This simple fact causes additional difficulties when a solar collector testing loop is installed in a indoor laboratory and also for the conditions of outdoor measurements. In order to achieve the desired flexibility for testing indoor, outdoor and on systems installed in the field we followed the concept to install each component of the testing loop on its own carriage with wheels.

|

Figure 4: Some of the components of the solar air collector testing loop: one of two gas turbine volume flow meters, one of two ventilators, electric control cabinet and data acquisition, water-to-air heat exchanger. The water side is connected to a thermostat by which the inlet temperature of the collector to be tested is controlled. All components are well insulated. They are covered with weatherable protection housings which are not seen in the pictures. |

Figure 5 shows the test loop installed for outdoor air collector tests using the solar tracker. Figure 6 shows the situation, when the same components are used for field tests, i. e. when the collector is installed already and tests have to be made in situ. In these measurements the water-thermostat was not used. Therefore it is more difficult to control the inlet temperature of the collector. It can be achieved to a certain extent by mixing ambient air with the heated air from the collector outlet. But of course, the accuracy of the measurements decreases a bit and the range of inlet temperatures available also depends on the power of the collector. Another challenge of field measurements of

collectors installed in a fixed position is to correctly take care of the influence of the Incidence Angle Modifier IAM. (But this is not different from corresponding water-collector performance measurements and not special for air-collectors.)

|

Figure 5:Air-collector testing loop installed for outdoor tests using the solar tracker at Fraunhofer ISE. |

|

Figure 6: Components of the air-collector testing loop used in a field test and not in one of our laboratories. |

|

|

|

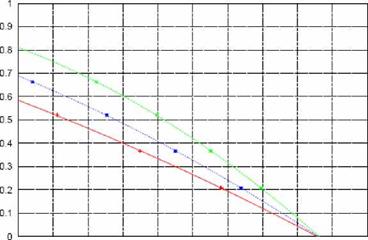

Figure 8 shows an example of an efficiency curve of a flat-plate air-collector with a selective absorber, measured under the solar simulator at Fraunhofer ISE. The air flows under the absorber plate which has downward-oriented fins to increase the heat exchanging surface from the absorber to the fluid. In order to give the complete information from the measurements we always use all three possibilities to present the collector efficiency: In the term (Txy-Tamb)/G on the x-axis, Txy can be choosen to be the mean fluid temperature Tm (defined as in EN12975 as the arithmetic mean value of Tin and Tout) or the collector inlet temperature Tin or the collector outlet temperature Tout. A |

|

* § cn ІП Oi |

|

5 |

|

0 0.01 002 0.03 0.04 0.05 0 06 0 07 0.08 0.09 0.1 |

|

(Txy-Tamb)/G in (K m2)/W |

|

Figure 8: Measured efficiency curves of a flat-plate air-collector: The collector reference temperature Txy is

Tin, Tm, Tout respectively for the curves from bottom to top.

We have started to improve our testing facilities to be able to carry out very exact air collector performance measurements. We will further improve them in the near future. Air collectors may be characterized exactly based on the same principles as described in EN12975. This concerns not only the performance measurements but also all functional and quality tests defined in EN12975.