The welding of aluminium and its alloys

Strength loss due to welding

In order to effect a weld the components to be joined are heated to a high temperature, in the case of fusion welding above the melting point of the parent metals, and brought together to enable the components to coalesce. The heat of the welding operation is conducted into the parent metal such that in any welded joint there are three distinct areas - the weld metal in a fusion welded joint, the HAZ in the parent material and the unaffected parent metal. The HAZ may be further subdivided into areas with particular properties depending upon the alloy system involved. Since the HAZ will have experienced one or more cycles of heating and cooling the properties may be radically different from those of the unaffected parent metal. This is particularly the case with those aluminium alloys that have been strengthened by either cold working or precipitation hardening. One aspect of this is the width of the HAZ, a function of the high thermal conductivity of aluminium and the consequent size of the area where there has been a substantial loss of strength. Only when the alloy is in the as-cast or annealed condition will the properties of the HAZ match those of the parent metal.

2.4.1 Weld metal

In a fusion weld the weld metal is an as-cast structure consisting of a mixture of the filler metal, if added, and the parent metal(s). The properties of this weld depend upon the composition, the quality and the grain size of the deposit. These in their turn depend on the parent and filler metal compositions, the amount of dilution, the quality of the welding process and the welder and, lastly, the rate of solidification. With the exception of a couple of 2XXX filler wires most filler metals available are not capable of being age hardened, although dilution with parent metal may enable some age hardening to take place. Fast solidification rates will give a finer grain size and hence better mechanical properties than slow solidification rates. Small weld beads therefore generally have better properties than large weld beads and a higher resistance to hot cracking. In the root pass, however, a small cross-section weld bead may increase the risk as it will be required to carry the contractional stresses and restraint.

There is very little that can be done to improve the properties of the weld metal. Solid solution strengthening can be useful and the selection of the appropriate filler metal can significantly contribute to a high weld metal strength. As a general rule the weld metal will match the parent metal properties only when the parent metal itself is in either the as-cast or annealed condition. Where cold work has been used to increase the strength of the parent metal it is not practicable to match these by cold working the weld. The lower strength in the weld metal must therefore be accepted and compensated for in the design. With some of the precipitation-hardening alloys a post-weld ageing treatment can be carried out to increase the strength of the weld metal, provided that the weld metal contains those alloying elements which will give precipitation hardening as mentioned above. The effectiveness of this heat treatment will depend upon the filler metal composition and dilution. For example, a single pass AC-TIG weld in a 6061 series alloy made with a 4043 filler metal will give an ultimate tensile strength of around 300N/mm2 in the post-weld aged condition, a multi-pass MIG weld made with a 4043 filler will give approximately 230N/mm2. Changing the 4043 filler to a 4643, which contains only 0.2% of magnesium, will improve the strength after post-weld ageing to match that of the autogenous AC-TIG weld. This is a further example of the importance of the correct selection of filler metals and the control of consistency during welding of the aluminium alloys.

2.4.2 Heat affected zone

As mentioned earlier, alloys in the as-cast or annealed condition may be welded without any significant loss of strength in the HAZ, the strength of the weldment matching that of the parent metal. Where the alloy has had its strength enhanced by cold work or precipitation hardening then there may be a substantial loss of strength in the HAZ.

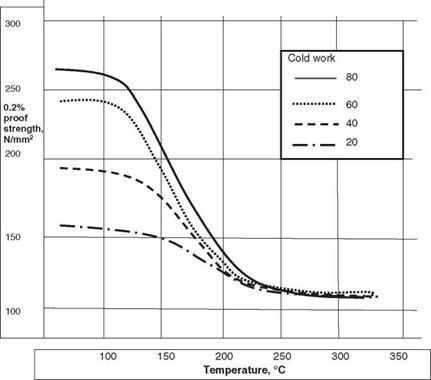

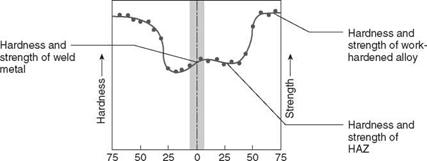

The cold worked alloys will experience a loss of strength due to recrystallisation in the HAZ. Recrystallisation begins to take place when the temperature in the HAZ exceeds 200 °C and progressively increases with full annealing taking place over 300°C as illustrated in Fig. 2.17. This shows a 1XXX alloy cold worked to different amounts and heat treated at a range of temperatures, showing how the annealing heat treatment results in a major loss of strength. The result of this in practice is illustrated in Fig. 2.18 which shows a 5XXX alloy TIG welded.

A similar picture can be seen in the heat-treatable alloys. The situation here is somewhat more complex than with the work-hardened alloys but

|

2.17 Effect of annealing temperature on cold work and strength. |

|

weld

Distance from centre of weld (mm) |

2.18 Effect of welding on strength in cold worked alloy.

|

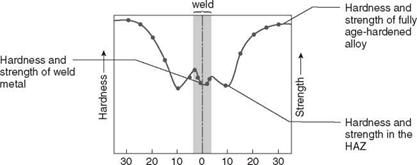

Distance from centre of weld (mm) 2.19 Effect of welding on 6061 T6 age-hardened alloy - as welded. |

similar losses in tensile strength can be found. The loss is caused by a dissolution of the precipitates in the 2XXX series alloys and a coarsening or overageing of the precipitates in the 6XXX and 7XXX alloys. These effects are illustrated in Fig. 2.19. Greater detail on these effects for individual alloys can be found in Chapter 3.

One last comment is the potential for the loss of alloying elements from the weld pool that may result in a reduction in strength. It is true that some elements, mainly magnesium with its low boiling point and lithium which is highly reactive with oxygen, may be lost or oxidised during welding. There is, however, a dearth of information quantifying any effects, which suggests that it is not perceived as being a problem. Loss of magnesium is worst when MIG welding, resulting in the sooty deposit occasionally seen along the weld toes but in this case, and in the case of lithium, careful attention to gas shielding will minimise any problem.