The welding of aluminium and its alloys

Process principles

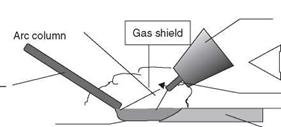

The basic equipment for TIG welding comprises a power source, a welding torch, a supply of an inert shield gas, a supply of filler wire and perhaps a water cooling system. A typical assembly of equipment is illustrated in Fig. 6.2.

For welding most materials the TIG process conventionally uses direct current with the electrode connected to the negative pole of the power source, DCEN. As discussed in Chapter 3 welding on this polarity does not give efficient oxide removal. A further feature of the gas shielded arc welding processes is that the bulk of the heat is generated at the positive pole. TIG welding with the electrode connected to the positive pole, DCEP,

|

Filler wire if required |

|

Weld pool |

|

Ceramic gas shroud |

|

Travel direction |

|

|

|

Tungsten — electrode Solidified weld metal |

6.1 Schematic of the TIG welding process.

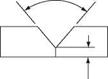

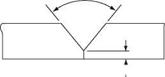

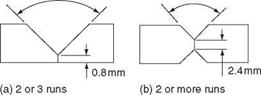

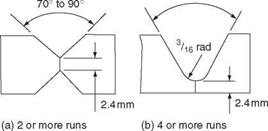

Table 6.1 Suggested welding preparations for TIG welding from BS 3019

|

Thickness (mm) |

|

Remarks |

Edge preparation

|

20swg = 0.9 mm and 16swg = 1.6mm 3.8mm |

|

1 |

||

|

J |

1 V |

|

Flanging should be used only where square edge close butt welds are impracticable

Where a backing bar cannot be used, welding from both sides is recommended

4.8mm

|

|

|

70° to 90° |

|

1.6 mm |

|

6.4mm |

|

70° to 90 |

|

|

|

|

|

1 or 2 runs I 1.6 mm 70° to 90° |

|

70° to 90° |

|

9.5mm |

|

(a) If no backing bar is used, chip back to sound metal and add sealing run (b) Chip back first run to sound metal before welding underside |

|

If no backing bar is used, it is good practice to chip back to sound metal and add sealing run |

Thickness Edge preparation Remarks

(mm)

|

12.7 mm |

|

|

|

60° |

|

(a) 4.8-6.4mm (b) Over 6.4-12.7 mm |

|

|

|

90° |

|

90° |

|

/ 1 |

||

|

2.4 mm |

||

|

2.4 mm |

|

(a) Chip back first run to sound metal before welding underside. Preheating may be necessary (b) Chip back first run to sound metal and add sealing run. Preheating may be necessary Preparation for vertical butt welds using double operator technique. One pass only required (a) (b) |

|

|

6.2 Manual DC-ve TIG welding repair of aluminium castings using helium shielding gas. Courtesy of TPS-Fronius Ltd.

|

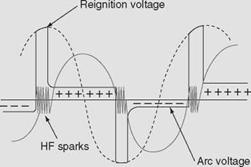

— Voltage across arc gap Welding current --- Open circuit voltage |

6.3 HF current and its effect on voltage and current.

results in overheating and melting of the electrode. Manual TIG welding of aluminium is therefore normally performed using alternating current, AC, where oxide film removal takes place on the electrode positive half cycle and electrode cooling and weld bead penetration on the electrode negative half cycle of the AC sine wave. The arc is extinguished and reignited every half cycle as the arc current passes through zero, on a 50 Hz power supply requiring this to occur 100 times per second, twice on each power cycle. To achieve instant arc reignition a high-frequency (HF), high-voltage (915000 V) current is applied to the arc, bridging the arc gap with a continuous discharge. This ionises the gas in the arc gap, enabling the welding arc to reignite with a minimum delay (Fig. 6.3). This is particularly important on the DCEP half cycle.

Aluminium is a poor emitter of electrons, meaning that it is more difficult to reignite the arc on the electrode positive half-cycle. If there is any delay in reignition then less current flows on the positive half cycle than on the negative half cycle. This is termed partial rectification and can eventually lead to full rectification where no current flows on the positive half cycle. The arc becomes unstable, the cleaning action is lost and a direct current component may be produced in the secondary circuit of the power source, leading to overheating of the transformer. This is prevented on older power sources by providing an opposing current from storage batteries and in more modern equipment by inserting blocking condensers in the power source circuit.

The HF current is operating continuously when the arc is burning in the AC-TIG process. An important word of caution relates to this - the HF current can track into other equipment in the vicinity of the arc and

|

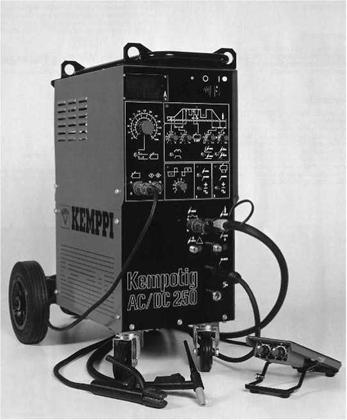

6.4 Inventor-based multi-function MMA/TIG power source capable of providing square wave AC for the welding of aluminium. Courtesy of Kemppi (UK) Ltd. |

can seriously damage electronic circuits, can cause malfunctions and uncontrolled movements of robotic systems and NC machines and can affect the functioning of telephones and computer networks. Where HF current is used precautions must be taken to prevent damage by adequate shielding of equipment and electronic circuits, perhaps by the use of a Faraday cage.

6.2.1 Square wave power sources

The most modern equipment (Fig. 6.4) uses solid state circuitry and is capable of providing a square wave AC current rather than the sinusoidal wave form of the older equipment. These power sources can be adjusted to vary the wave frequency and the balance of positive and negative current by shortening or extending the length of time spent on the positive or negative half cycle. The latest inverter-based units provide a high degree of control with the electrode negative duration time capable of being adjusted from 50% to 90% of the cycle. Increasing the frequency results in a more focused arc, increasing penetration, enabling faster travel speeds to be used and reducing distortion. Increasing the electrode negative portion of the cycle will give similar results of increased penetration and faster travel speed although the cathodic cleaning effect will be reduced. Biasing the square wave more towards the electrode positive half cycle will reduce penetration, useful when welding thin materials, and will widen the bead profile.

Another very important difference between older units and the inverter - based power sources is that the square wave cycle passes through the zero welding current point many times faster than with a sinusoidal wave. It is possible to dispense with continuous HF current for arc stabilisation, removing the risks of damaging sensitive electronic equipment. High frequency will still be needed to initiate the arc, however, so a small risk remains. The lack of continuous high frequency may also result in an unstable arc on very clean, etched surfaces or on the weld metal. Inverter power sources are also capable of overcoming a problem encountered when using two arcs close together. Welding current can track from one power source to the other, damaging the circuitry. With the very latest equipment the two arcs are matched.

Square wave power sources have a further advantage in that tungsten ‘spitting’, where the electrode tip spalls off and contaminates the weld pool, can be reduced. Reducing the electrode positive portion will reduce the overheating that causes tungsten spitting.

6.2.2 Shielding gas

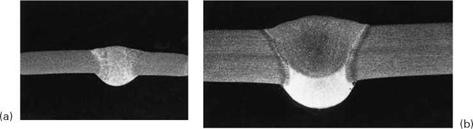

The preferred gas for the AC-TIG welding of aluminium is argon, although helium and argon-helium mixtures may be used. Argon gives a wide, shallow penetration weld bead but will leave the weld bright and silvery in appearance. The easiest arc ignition and most stable arc will also be achieved with argon. Typical butt welds in 3 mm and 6 mm plate are illustrated in Fig. 6.5 and a fillet weld in 6 mm thick plate is shown in Fig. 6.6. A table of suggested welding parameters for use with argon as a shield gas is included as Table 6.2. Typical current ranges for a range of plate thicknesses are illustrated graphically for butt welds in Fig. 6.7 and for fillet welds in Fig. 6.8.

Helium increases arc voltage with the effect of constricting the arc, increasing penetration but making arc ignition more difficult, and adversely affecting arc stability. Some of the modern welding power sources are equipped with a facility to start the weld with argon and, once a stable arc

|

|

6.5 AC-TIG argon shielded (a) unbacked 3mm sheet, single pass, flat position; (b) unbacked 6mm thick plate, two pass, flat position.

6.6 AC-TIG argon shielded, 6mm thick plate, single pass, horizontal-vertical.

|

25 r- 12 10 6.0 5.0 3.0 2.0 1.6 1.0 |

|

MATERIAL THICKNESS (mm) |

С

TOC o "1-5" h z l~ I

Г 1

I 1

I I

I I

- I I

150 200 250

WELDING CURRENT (A)

6.7 Typical TIG current ranges for various material thicknesses.

|

TIG WELDED FILLET JOINTS |

RUNS |

FILLER mm |

SPEED mm/min |

|||

|

і і і |

і |

і i |

4.8 |

150 |

||

|

- |

— |

- |

4.8 |

150 |

||

|

- |

— |

- |

4.8 |

200 |

||

|

- |

— |

- |

4.8 |

280 |

||

|

- |

- |

- |

3.2 |

230 |

||

|

- — |

- |

2.4 |

190 |

|||

|

і і i |

i |

і i |

- |

1.6-2.4 |

200 |

|

50 |

|

100 |

|

400 |

|

E E, CD CD Ш О □: і- _i < □c ш <c |

|

9.5 8.0 6.4 4.8 3.2 2.0 1.6 0 |

150 200 250 300 350

WELD CURRENT 6.8 Typical TIG welding parameters for fillet welding.

|

Table 6.2 Suggested welding parameters - argon gas shielding

1. The conditions shown are for the PA (flat) position. A reduction in current of around 10% should give acceptable parameters for other positions. 2. The thickness is limited to 10mm. Above this the TIG process is rarely used because of economic considerations. |

0

|

(a) |

|

6.9 DC-TIG helium shielded (a) unbacked 3mm thick plate, single pass, flat position; (b) unbacked 6mm thick plate, single pass, flat position. |

is established, for an automatic change-over to helium to be made. For comparison purposes with the argon shielded welds typical cross-sections of butt welds in 3 mm and 6 mm thick plate and a fillet weld in 6 mm thick plate are shown in Fig. 6.9 and Fig. 6.10. In the UK helium is a more expensive gas than argon - some five to six times more - and provides little or no arc cleaning action. Indeed, in some circumstances, the use of helium can result in ‘soot’ being deposited in the HAZ and although this may normally be removed by wire brushing, it can be difficult to remove. For these reasons 100% pure helium is rarely used in manual AC-TIG welding.

The addition of argon to helium improves arc striking and arc stability. Travel speeds and penetration will be less than with pure helium but greater than with argon. It is possible to control bead width and penetration by varying the amount of argon in the mixture. The most popular mixture in the UK is 25% helium in argon.

|

6.10 DC-TIG helium shielded, unbacked 6mm thick plate, single pass, horizontal-vertical. |

The power source controls should provide for both pre-flow and post-flow of the shield gas. A pre-flow is used to purge the hoses and the torch and to protect the electrode when the arc is established. Maintaining the flow of gas when the weld is terminated is also necessary to protect both the weld pool and the electrode from oxidation as they cool from welding temperature. Gas flow rates are important in ensuring adequate gas coverage. ‘Bobbin’ type flow meters are often used attached to the regulator to control flow. Any restriction between the bobbin meter and the torch means that the flow rate will not be set accurately. It is a good idea to validate meter readings by attaching a flow meter to the torch gas shroud and monitoring the flow. Flow meters are also calibrated for a specific gas and will give inaccurate readings if they are used to control the flow of other gases or gas mixtures. This is particularly important when using helium or argon-helium mixtures.

6.2.3 Welding torches and cables

There is a wide variety of welding torches available with torch ratings ranging from some tens of A to 450 A, the appropriate rating depending essentially on the thickness of the metal to be welded. Most of the modern torches (Fig. 6.11), are provided with current controls built into the torch handle. All but the lightest torches, i. e those rated to operate below around 200 A, are water cooled and the same water may be used to cool the power cables, enabling them to be lighter and more flexible.

Overheating of the torch can melt the brazed joints within the torch or the plastic tube that sheaths the power cable and it is important that

|

6.11 Modern TIG torch. Courtesy of TPS-Fronius. |

|

Table 6.3 Suggested nozzle sizes and gas flow rates

|

the correctly rated torch is selected for the current to be used in production. The manufacturer’s rating for a torch may be based on DC-positive current and a torch rated in this way will need to be de-rated when used with AC.

Most of the torches can be fitted with either metal or ceramic gas shrouds although the ceramic shrouds are the most popular. They are, however, rather more easily damaged than the metal shrouds. Nozzle sizes for a range of thicknesses and gas flow rates are given in Table 6.3. It is recommended that a device known as a gas lens is fitted to welding torches. This is a mesh disc inserted into the torch which assists in providing a more efficient, laminar flow gas shield with better coverage. The beneficial effect of a gas lens is illustrated in Fig. 6.12.

6.12 Demonstration of laminar flow by use of gas lens. Courtesy of TWI Ltd.

6.2.4 Tungsten electrodes

There are several types of electrodes available for TIG welding. These include pure tungsten and tungsten alloyed with thoria (ThO2) or zirconia (ZrO2). These compounds are added to improve the arc starting characteristics, to stabilise the arc and to extend the electrode life. Recently there has been a move towards the use of other rare earth elements such as caesium, cerium or lanthanum, which are claimed to extend the electrode life further and will reduce the radiation risk arising during the grinding of thoria containing electrodes. Zirconiated electrodes are preferred for AC - TIG welding since these have a higher melting point than either pure tungsten or thoriated tungsten electrodes and can therefore carry higher welding currents, are more resistant to contamination and are less likely to spall.

The electrode tip assumes a hemispherical shape during welding. It is important that this shape is maintained if a stable arc is to be achieved. The

|

D |

|

6.13 Recommended tungsten electrode shape. |

|

Table 6.4 Recommended electrode diameters - zirconiated tungsten electrodes and argon shield gas

|

electrode tip should be lightly tapered to assist in the formation of the rounded tip as illustrated in Fig. 6.13.

Too small an electrode for the current will lead to overheating and possibly melting, resulting in tungsten contamination of the weld pool. Too large an electrode for the current will result in arc stability problems and a very wide weld pool. Electrodes are available in diameters ranging from 0.3 mm to 6.4 mm. Recommended electrode diameters and welding currents are given in Table 6.4. The electrode should not protrude from the nozzle by more than about 6 mm, although this may be extended by up to 10 mm if a gas lens is fitted to the torch. This extension can be useful if access is restricted because of the ceramic nozzle fouling on the component.

Before production welding is started it is recommended that the electrode is preheated by forming an arc on a piece of aluminium scrap. This enables the rounded tip to be formed, allows the welder to check that the electrode is performing correctly and enables the arc to be reignited on the production component with ease. If the tip becomes contaminated or is damaged in any way it should be reground and reformed as above.

Table 6.4 is for square wave AC-TIG with a balanced wave form. If the current is biased to give a greater proportion of positive current the value will need to be reduced by an amount appropriate to the amount of imbalance in the wave form. If using a conventional balanced sine wave current then these values should be reduced by around 25%.

|

6.14 Angle of torch and wire workpiece. |

6.2.5 Manual welding techniques

6.2.5.1 Torch manipulation

The welder should attempt to maintain the shortest practicable arc length. In practice this is approximately equal to the electrode diameter. If the arc is too long penetration is decreased and the risk of lack of fusion defects is increased. Undercutting, poor bead shape and excessive bead widths may also be produced. Gas shielding may also be affected with entrainment of air into the shield gas giving oxide inclusions in the weld.

The torch should be held normal to the weld but pointing forwards towards the direction of travel, at an angle of around 80°. When welding joints of unequal thickness the arc should be directed more towards the thicker side of the joint. For fillet welds the torch should bisect the angle between the two plates. Weaving of the torch may be carried out but the weave width should be restricted to the diameter of the nozzle.

6.2.5.2 Filler rods

The filler rod, if used, should be fed into the leading edge of the weld pool with a slow, ‘dabbing’ action at an angle of 10-20° (Fig. 6.14). It should not be fed directly into the arc column as this tends to cause spatter and may accidentally contaminate the electrode. A steeper angle than 10-20° restricts the welder’s view of the weld pool. The tip of the filler rod should be held inside the gas shield while it is hot to prevent oxidation. As the component thickness increases the filler rod diameter increases, necessitating an increase in arc length. Bear in mind that too long an arc can cause oxide entrapment problems. A large diameter rod can also shield the material ahead of the weld pool from the cleaning action of the arc and this may also lead to oxide entrapment.

|

6.15 Oxide intrusion and cracking associated with suck-back. |

6.2.5.3 Root bead penetration

It is possible to produce fully fused root beads without backing using AC - TIG. Up to 3 mm thickness the weld can be made without a weld preparation but above this a V - or U-preparation will be necessary to achieve full fusion. Root gaps should be avoided. A skilled welder will use the appearance of the weld pool to judge when a fully penetrating root bead has been produced. When full penetration has been achieved the weld pool will sink and will have a bright shiny surface. A U-preparation will make it easier for the welder to judge when this happens. In thicker material when using a V-preparation the arc tends to favour the side walls instead of acting directly on the root, sometimes leading to lack of fusion type defects. An alternative to a U-preparation that avoids this problem is to use a V- preparation with an included angle of at least 90°.When welding root passes in position, particularly overhead, root concavity or ‘suck-back’ is a problem. This requires the filler rod to be pushed into the weld pool to disrupt the oxide film and to form a convex bead.

The oxide film that causes suck-back is also responsible for a feature known colloquially as a ‘baby’s bottom’, a very accurate description of the appearance of this root defect (Fig. 6.15). Oxides tend to migrate to the centre of the root penetration bead. When these become excessive the centre of the bead sinks to produce a deep groove along the centre line that may also be associated with hot cracking. In butt welds a very wide weld bead caused by a large root gap or a high welding current will also contribute. This defect is particularly prevalent in corner joints in thin sheet assemblies and is caused by a failure to clean the weld preparations and the filler wire adequately. It has been found helpful to use unbalanced square wave AC to increase the arc cleaning action and pulsed square wave AC, with a heavy bias towards DC positive, has been successfully used in particularly troublesome applications.

Permanent backing strips may be used to simplify root bead control. These require a very good fit-up between the underside of the plates and the backing strip to prevent lack of fusion or suck-back type defects. To achieve good penetration into the backing strip there must be a root gap of at least 1.5 times the electrode diameter and this gap must be maintained along the full length of the component. This means that the joints must be adequately tack welded together.

6.2.5.4 Weld termination

Controlled finishing of a weld pass is important if defects are to be avoided. Abruptly switching off the welding current can cause craters, piping (elongated pores) and cracks in the finished weld pool. When finishing the weld it is necessary to reduce the welding current gradually and to decrease the arc length as the arc fades away, adding filler rod until such times as the arc is extinguished. If a crater begins to form the arc should be briefly reestablished, additional filler metal added and the arc decayed as before. On thin material the travel speed may be increased to a point at which it can be seen that the metal has ceased to melt.

6.2.6 DCEN helium TIG welding

Welding aluminium with the electrode connected to the negative pole can be carried out using helium as the shield gas. This gives a higher temperature arc and increased penetration compared with AC-TIG but the oxide removal action of the positive arc is absent. This means that cleaning of the item to be welded assumes even more importance than when using AC. The higher heat input and the deeper penetration means that higher travel speeds can be used and a wider range of thicknesses may be welded than with AC-TIG, although the high travel speeds do mean that the process is rarely used in a manual context but is almost entirely mechanised. Typical single pass welds using helium as the shield gas are illustrated in Fig. 6.9 (butt welds) and Fig. 6.10 (fillet weld). Note in particular the wider and more deeply penetrating fillet weld bead compared with argon shielding. Suggested welding parameters for butt and fillet welding using helium are given in Table 6.5.

|

Thickness (mm) |

Joint type |

Root gap /face (mm) |

Current (A) |

Voltage (V) |

No. of passes |

Filler diam. (mm) |

Travel speed (mm/min) |

|

0.8 |

sq. butt |

nil |

20 |

20 |

1 |

1.2 |

420 |

|

1 |

sq. butt |

nil |

26 |

20 |

1 |

1.6 |

420 |

|

1.5 |

sq. butt |

nil |

45 |

20 |

1 |

1.6 |

480 |

|

2.4 |

sq. butt |

nil |

80 |

17 |

1 |

2.4 |

300 |

|

2.4 |

fillet |

130 |

14 |

1 |

2.4 |

540 |

|

|

3.2 |

sq. butt |

nil |

120 |

17 |

1 |

3.2 |

480 |

|

3.2 |

fillet |

180 |

14 |

1 |

3.2 |

480 |

|

|

6.3 |

sq. butt |

nil |

250 |

14 |

1 |

4.8 |

180 |

|

6.3 |

fillet |

255 |

14 |

1 |

4.8 |

360 |

|

|

10 |

90 V-butt |

nil face 6 |

285 |

14 |

2 |

4.8 |

150 |

|

10 |

fillet |

290 |

14 |

1 |

6.3 |

180 |

|

|

12.5 |

90 V-butt |

nil face 6 |

310 |

14 |

2 |

4.8 |

120 |

|

12.5 |

fillet |

315 |

16 |

2 |

6.3 |

180 |

|

|

20 |

90 double-V |

nil face 5 |

300 |

17 |

2 |

4.8 |

120 |

|

25.4 |

90 double-V |

nil face nil |

360 |

19 |

5 |

6.3 |

60 |

|

1. Ceramic nozzle size should be 12.7 mm. 2. The parameters shown are for welding in the PA (flat) position for the butt welds and the PB (horizontal) position for the fillets. |

Unlike AC-TIG where zirconiated electrodes are preferred, the best electrodes for DCEN welding are thoriated tungstens, which permit easier arc starting, maintain their tip shape longer and result in less tungsten spitting. The tip of the electrode should be tapered at an angle of 45° and the end blunted by grinding on a flat of about half the electrode diameter. A long tapered tip can result in shield gas turbulence, poor weld profiles and undercutting.

Wire feeding differs from that used in AC-TIG welding in that the wire tip should be fed into the weld pool by pushing the still solid wire into the pool and then withdrawing it when a sufficient amount of filler wire has been added, keeping the wire tip within the gas shield. The torch is then moved forward and a fresh weld pool established. This discontinuous method of welding assists in piercing the oxide skin on the weld pool surface and in increasing penetration. With temporary backing bars this technique enables square edge butt joints to be welded at thicknesses of up to 9 mm, provided that the welder has sufficient skill. Double sided square edge butt welds can be made successfully at up to 12.5 mm thickness. Above this thickness then a ‘V’ or preferably a ‘U’ preparation needs to be used to enable single sided unbacked butt joints to be made. It is recommended that an electrode with a fully tapered tip is used to concentrate the arc into the root of the joint when a weld preparation is to be welded.

One feature seen with helium shielded arc welding, which often gives cause for concern, is the formation of a black ‘soot’ along the heat affected zones of the weld. This ‘soot’ is not detrimental to the weld quality and can easily be removed by stainless steel wire brushing. If left in place between passes it can affect arc stability and is unsightly on a completed weld.