The welding of aluminium and its alloys

Access for welding

The two most common design faults are failing to recognise that full vision of the weld pool is essential for manual welding and that the weld must be at a comfortable distance from the operator, neither too close nor at a distance where the welder’s arm is at full stretch. These errors can frequently be recognised at the design stage and the benefits of requiring an experienced welding engineer to review draft drawings cannot be overemphasised. The distance from the operator’s head to the weld can easily be checked on drawings. Ideally this distance should be in the region of 200 mm minimum to 450 mm maximum. It should be remembered that the diameter of the welder’s helmet is about 300 mm and that this will affect the access requirements.

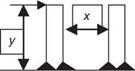

For a joint to be accessible for manual welding welders must be able comfortably to position themselves and their equipment if high-quality welds are to be produced. This requires sufficient space to permit free movement of the welding torch or electrode and to enable the torch to be presented to the weld pool at the correct angle. Detail design must also take into account the proximity of adjacent material which should be such that the welder is allowed an unrestricted view of the arc. The amount of space required will depend on the size of the equipment to be used, in particular the size of the torch. Welding aluminium with the gas shielded processes

For adequate access to the fillet welds between the two upright plates y should always be less than x

|

5.1 Access requirements for welding.

5.2 Access problems of angled plates or pipes. |

|

|

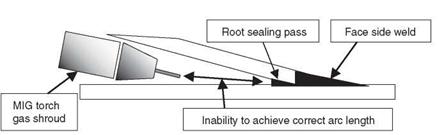

requires a large diameter gas shroud and a short arc length. This means that the welder’s view of the weld pool is more restricted than when welding a similar configuration in steel. The sketch in Fig. 5.1 illustrates a situation that is often encountered in practice where the designer has failed to take into account the need for adequate access. As a rule of thumb the distance between the plates should be as shown. A further limitation for TIG welding is the need to add a filler wire that restricts further the welder’s view of the arc and the ease of manipulation as both of the welder’s hands need to be in the work area.

The welding of attachments or nozzles to plates or pipes can present problems when the nozzle is presented to the surface at an angle less than 45°.Access into the acute angle is difficult, resulting in lack-of-fusion defects in the root of the weld as illustrated in Fig. 5.2.