Solar thermal collectors and applications

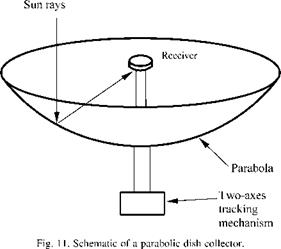

Parabolic dish reflector (PDR)

A parabolic dish reflector, shown schematically in Fig. 11, is a point-focus collector that tracks the sun in two axes, concentrating solar energy onto a receiver located at the focal point of the dish. The dish structure must track fully the sun to reflect the beam into the thermal receiver. For this purpose tracking mechanisms similar to the ones described in previous section are employed in double so as the collector is tracked in two axes.

|

|

Parabolic dishes have several important advantages:

1. Because they are always pointing the sun, they are the most efficient of all collector systems;

2. They typically have concentration ratio in the range of 600-2000, and thus are highly efficient at thermal-energy absorption and power conversion systems;

3. They have modular collector and receiver units that can either function independently or as part of a larger system of dishes.

The main use of this type of concentrator is for parabolic dish engines. A parabolic dish-engine system is an electric generator that uses sunlight instead of crude oil or coal to produce electricity. The major parts of a system are the solar dish concentrator and the power conversion unit. More details on this system are given in Section 5.6.3.

Parabolic-dish systems that generate electricity from a central power converter collect the absorbed sunlight from individual receivers and deliver it via a heat-transfer fluid to the power-conversion systems. The need to circulate heat - transfer fluid throughout the collector field raises design issues such as piping layout, pumping requirements, and thermal losses.

Systems that employ small generators at the focal point of each dish provide energy in the form of electricity rather than as heated fluid. The power conversion unit includes the thermal receiver and the heat engine. The thermal receiver absorbs the concentrated beam of solar energy, converts it to heat, and transfers the heat to the heat engine. A thermal receiver can be a bank of tubes with a cooling fluid circulating through it. The heat transfer medium usually employed as the working fluid for an engine is hydrogen or helium. Alternate thermal receivers are heat pipes wherein the boiling and condensing of an intermediate fluid is used to transfer the heat to the engine. The heat engine system takes the heat from the thermal receiver and uses it to produce electricity. The engine-generators have several components; a receiver to absorb the concentrated sunlight to heat the working fluid of the engine, which then converts the thermal energy into mechanical work; an alternator attached to the engine to convert the work into electricity, a waste-heat exhaust system to vent excess heat to the atmosphere, and a control system to match the engine’s operation to the available solar energy. This distributed parabolic dish system lacks thermal storage capabilities, but can be hybridised to run on fossil fuel during periods without sunshine. The Stirling engine is the most common type of heat engine used in dish-engine systems. Other possible power conversion unit technologies that are evaluated for future applications are microturbines and concentrating photovoltaics [92].