New developments in advanced welding

GMAW process measurement and control

This section includes a review of recent advances in GMAW process analysis. Topics include process sensing/monitoring, control, modelling, automation and robotics, simulations, arc physics/droplet transfer modes and fume and spatter control.

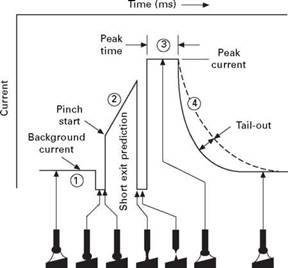

One of the major topics in GMAW process analysis has been the molten metal droplet detachment and transfer modes. For given ranges of wire electrode diameter, welding current and shielding gas, five modes of detachment have been recognised (Nadzam, 2003): (1) short-circuit, (2) globular, (3) axial spray, (4) pulsed-spray and (5) surface-tension transfer modes (Fig. 1.10) (Nadzam, 2003).

The forces governing the dynamic equilibrium during droplet detachment have been identified. They are: (a) electromagnetic forces associated with the welding current self-induced magnetic field, (b) gravity, (c) surface tension and (d) cathodic jet forces (Lancaster, 1984). Lately, variable polarity

|

1.10 Schematic representation of the surface tension-controlled droplet transfer mode (STT) (Nadzam, 2003). |

(VP-GMAW) has been shown to be effective also in controlling metal transfer and melting rate.

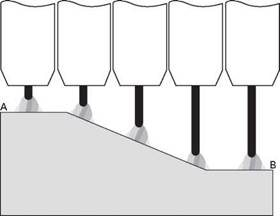

Traditionally, using a CV power source with inductance control proved to be excessively sensitive to arc length variations, responding with large wire speed and current responses. Therefore, feed-forward controls - also known as digital or reactive controls - have been introduced where the current can be modified independently from the wire speed. Advances in process control have been made especially using feed-forward algorithms, as demonstrated by their excellent adaptability to step responses when compared to the traditional feed-back control (Adolfsson, 1999). A resulting constant arc length control system is schematically shown in Fig. 1.11 (Himmlebauer, 2003), demonstrating the ability of the system to adjust to random variations in CTWD without changing the arc length.

Process control can also be very different in aluminium alloys when compared to that in steel. For the same wire electrode extension, the Al GMAW was found to be up to 28 times more sensitive to variations in wire feed speed than the mild steel electrode (Quinn, 2002). Because of the higher electrical and thermal conductivity of Al compared to steel, conductive heat transfer dominates the dynamic equilibrium between burn-off and feed rate, compared to convection and resistive heating in steels. For instance, the

|

1.11 Illustration of the principle of constant arc length control when using digital power systems (Himmelbauer, 2003). |

voltage drop across the same electrode extension length was one order of magnitude less in Al than it was steels (0.03 V compared to 0.3 V). In most cases, the GMAW process responds in aluminum more dramatically to perturbations in welding current or wire speed setpoints.

Process stability in pulsed GMAW of titanium can be improved by active droplet transfer control by adding peak current pulse in the one-drop-per - pulse or ODPP method or excited droplet oscillation (Zhang and Li, 2001). Application of statistical process design has been used in the past decade to optimise GMAW welding parameter development (Allen et al. 2002). Methods involve classical design-of-experiments or DOE, heuristic parameter optimisation, neural network modelling and Taguchi methods. Generally, independent and dependent variables are identified using regression analysis of the weld quality and empirical equations are developed to predict optimum parameters for new situations. Invariably, the original experiments are limited to the base material type, joint design and fitup, shielding gas type, etc. and most such articles end up apologising for the narrow range of applicability of their predictions (Subramaniam et al., 1999).

This section attempts to describe GMAW process outputs such as microstructure/property relationships in ferrous and non-ferrous alloy welding.

1.4.1 Microstructure/property relationships

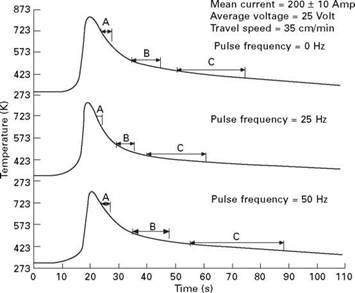

Although pulsed current power sources (GMAW-P) have originally been developed to improve process stability, penetration and deposition rates, it

|

1.12 Increased pulsed frequency reducing cooling rate of HAZ adjacent to fusion line of Al-alloy weld (Ghosh et al., 1994). |

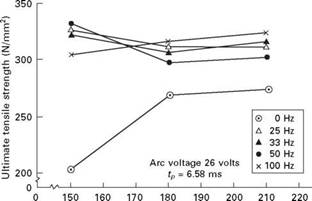

was also found that they could control the weld deposit properties. The solidification mechanism of weld metal during GMAW-P welding differs from that of continuous current welding due to intermittent movement of heat towards the solidification front. During pulsed current GMA welding, the solidification of the molten pool takes place primarily in two steps: one during the pulse off time period, and the second during development of a weld spot resulting from the next pulse. Thus the weld deposit microstructures and heat affected zone (HAZ) width can be varied (Ghosh et al., 1990a) as GMAW-P waveform types can produce a wide range of metal transfer energy levels, deposition rates and resulting thermal cycles (Gupta et al., 1988) (Fig. 1.12). By this course of action the pulsed current GMA welding improves the weld property in comparison with that of the conventional continuous current GMA weld (Ghosh et al., 1990b) (Fig. 1.13).

In out-of-position GMAW-P, the appropriate selection of pulse parameters, such as mean current (/m), peak current (Ip), base current (Ib), pulse duration (tp) and pulse frequency (f), in combination provides a droplet velocity. The droplet is propelled or rejected by gravity, depending on the welding position, and it imposes a control over the superheated droplet and the resulting fluidity of the weld pool. Successful use of pulsed current GMA welding to produce weld of desired quality is very much dependent upon proper control over the Im Ip, Ib, f, tp and pulse off (base) time (tb). Because of the interrelated nature

|

Mean welding current (Amp) 1.13 Effect of pulsing on the tensile strength in GMAW-P when compared to continuous wave (0 Hz). (Ghosh et al., 1991). |

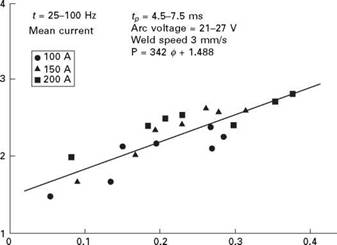

of pulse parameters, control of weld quality is possible by establishing a correlation with a dimensionless factor f = [(Ib/Ip)/tb], where tb is the pulse - off time, expressed as [(1/f)-tp].

1.4.2 GMAW-P welding of C-Mn steels

It was found that in case of FCAW-P bead-on-plate deposits, the pulse parameters and changes in arc voltage affects the microstructure and hardness of the weld deposit and HAZ, the width of HAZ and increases the porosity content of the deposit (Ghosh and Rai, 1996) (Fig. 1.14). The pulse parameters and arc voltage (due to their influence on Ip and 4) are found to affect the characteristics of the weld deposit and hAz via the factor f. At a given welding speed and arc voltage the width and hardness of HAZ show a relatively decreasing and increasing trend in the linear relationship with the factor f. Optimised pulse parameters can improve the weld quality, i. e. reduce porosity and optimise microstructure/hardness in the weld deposit and HAZ. GMAW-P in the welding of large diameter cross-country pipelines is useful for reducing the occurrence of incomplete fusion defects. The superiority of using the GMAW-P process over the short-circuiting arc conventional GMAW process in a vertical-up weld deposition has been marked by a significant enhancement of the tensile, impact and fatigue properties of the weld joint of C-Mn structural steel. The variation in microstructures of the weld metal and HAZ, the geometry of the weld deposit, and the properties of the joint with a change in pulse parameters maintains a good correlation to the factor f. It has been reported that, at a given arc energy, the variation in f significantly influences the morphology of the weld deposit, becoming finer with increased

|

f 1.14 Effect of pulse parameter on porosity content of pulsed current GMA weld deposit of C-Mn steel (Hussain et al., 1999). |

f. Showing a general tendency to fracture from the weld deposit, the fatigue life of a pulsed-current weld becomes higher than that of the conventional short-circuiting arc GMA weld. Again, the most likely reason for this is the greater hardness of the weld deposit and the corresponding tensile strength. As fatigue failure initiation life has been known to be proportional to the tensile strength, it is probable that an increase in f had an indirect effect on fatigue life. Reduced net heat input in GMAW-P resulted in increased cooling rates and higher HAZ hardness in high performance steels, when compared to continuous wave GMAW welding using the same calculated arc energy (Adonyi, 2002).

1.4.3 GMAW-P welding of Al alloys

Variation of pulse parameters in single and multi-pass pulsed current GMA welding of Al alloys up to 25 mm thickness significantly affected the geometry, microstructure, and mechanical properties of weld joints (Ghosh et al., 1990a; Ghosh et al., 1990b; Ghosh and Hussain, 2002). GMAW-P at an average current level above the globular-to-spray mode transition current of the filler wire with suitable combination of pulse parameters significantly refines the microstructure of weld deposit and reduces the width of recrystallized HAZ (Ghosh et al., 1990a), when compared to continuous current GMAW deposited at the same average current level. Again, the most likely reason for this behaviour is the increase in HAZ cooling rates and lower peak temperatures attained within a given distance from the fusion line.

GMAW-P welding has also been found to improve the tensile strength and ductility of the weld joint of Al-Zn-Mg alloys in comparison to those of its conventional GMA weld, where the failure usually initiates in the Al-Mg weld deposit. The improvement in weld properties is primarily attributed to the refinement of the microstructure, reduction in porosity content and resulting weld geometry, which favourably control the dilution and zinc pickup from the base metal, forming strengthening precipitates in the weld deposit as identified by the X-ray diffraction studies. It is believed that GMAW-P improves the fatigue life of the weld by influencing the m and C values of the Paris law of crack growth rate expressed as da/dN = C(DK)m where a is the crack length, N is the number of loading cycle, DK is the range of stress intensity factor and C and m are the material constants (Ghosh et al., 1994). The improvement in fracture mechanics properties is primarily attributed to the synergic effects of refinement of microstructure and amount of zinc pickup due to dilution of Al-Mg weld deposit by the base metal (Ghosh et al., 1991; Ghosh et al., 1994; Hussain et al., 1997; Hussain et al., 1999).

1.4.4 GMAW-P in stainless steel cladding

In single pass stainless steel cladding on structural steel plates the use of pulsed current GMAW-P, produces comparatively increased clad layer thickness, lowered penetration when compared to overlays produced by continuous current GMAW. Overlaying using GMAW-P also enhances the hardness of the clad layer and reduces the hardness of diffusion layer formed at the interface of stainless steel cladding with the structural steel (Ghosh

et al., 1998). It can be assumed that all these effects are caused by the lower net heat input in GMAW-P and accelerated cooling rates, when compared to continuous GMAW with equivalent average arc energy. Lower net heat inputs of up to 20% (Hsu and Soltis, 2002) and 15 % (Joseph et al., 2002) were found using calorimetry and the arc instantaneous power measurements. Note that the initial arc efficiency was ~70% for the GMAW process in general (Fig. 1.15). Similar lower heat inputs relative to the arc energy were found in GMAW-P.