Optimizing of a new tracking systems for small parabolic trough collectors

D. Ciobanu1*, I. Visa1* and D. Diaconesc1*

1 Transilvania University of Brasov, Centre for Sustainable Development, Eroilor Street, Brasov, Romania

* Corresponding Author, daniela. ciobanu@unitbv. ro

Abstract

Concentrator collectors are generally used in order to increase the amount of energy absorbed from the Sun. These collectors use only the direct radiation, being equipped usually with a single axis tracking system. The paper refers to parabolic trough collectors, whose geometry imposes one axis tracking system. In order to set the kinematic and dynamic condition necessary for the tracking system, it is considered as a math example the month of March when the average day time is of 12 hours. Thus, the reflector should rotate 1800 during the 12 hours. The maximization of system efficiency is obtained by operating the collector at specific moments aiming to minimize the energy consumption during the tracking generation.

The dynamic behavior of the tracking system is obtained based on the modeling and simulation of the mechanism by using ADAMS software.

Keywords: solar-thermal energy conversion, tracking system, cam mechanism, multibody system method

The function of a solar collector is simple; it intercepts incoming insolation and turns it into thermal energy that can be applied to meet a specific demand.

|

Solar collectors are classified depending on the working principle in plate and concentrator. Plate collectors use the global radiation while the concentrator collectors use only direct radiation. Most common concentrator collectors are parabolic trough, Fig.1, a, central receiver and parabolic dish, Fig. 1, b, [1].

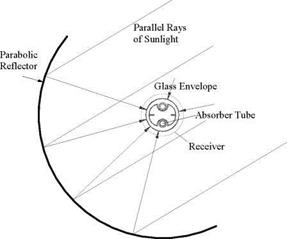

A parabolic trough concentrates the incoming solar radiation into a line running along the length of the trough, Fig. 2. A tube (receiver) carrying a transferring heat fluid, is placed along this line absorbing the concentrated solar radiation and heating the inside fluid [2, 3, 4].

|

For a better concentration of the solar radiation, due to the change of sun position on the sky, these collectors are equipped with tracking systems.

Tracking systems are classified by their motions. Rotation can be round a single axis (which could have any orientation but which is usually horizontal East-West, horizontal North-South, vertical, or parallel to the earth axis) or can be round two axes. The parabolic trough collectors are designed to operate with tracking rotation round one axis due to its geometry [1, 5].

Most common tracking systems use a gear box and a belt, [6, 7], rope or chain transmission. Collector trackers also use actuators or systems based on “hydro-mechanic”, [8] or gravitation, [9] principle.

Belt and rope transmission tracking systems require accurate maintenance and could generate errors; chain transmission cannot be used for large dimension collectors; systems based on “hydromechanic” principle have large dimension and those based on gravitation principle require a daily human intervention and are influenced by the environment temperature.

The proposed tracking system derives from a rotational (cardioids), [10] cam mechanism and oscillating role follower. A complex mechanism is generated by this, similar with a bolts gear. The mechanism uses two opposite cams and multi-followers generated by a wheel with two rows of bolts with half step delay. The advantages of this mechanism are: reduced dimensions by use of a two teeth gear - cams, lustiness, low costs due to a simple design, smooth motion and high efficiency due to the cycloidal gear, generating a more accurate operation comparing with other tracking systems. Equipped with a servo-engine and an adequate temporization, this mechanism can generate a controllable collector orientation.