Performance Evaluation

The performance analysis was carried out for a heliostat located 100m north of the tower. The orientation of the MMA is adjusted to obtain optimum annual reflection efficiency (270° azimuth angle, 37° elevation angle).

Three configurations of the MMA were evaluated:

• ideal MMA with antireflective coating (“ideal, ARC”)

• ideal MMA without antireflective coating (“ideal, noARC”)

• realistic MMA with antireflective coating (“real, ARC”).

The reference heliostat (“reference”) is included for comparison.

Figure 8 shows the results for the described configurations for noon at equinox (21.3. 12:00).

Details of the results are given in This characteristic is much more obvious when looking at the performance over a day.

Figure 10 shows the daily performance for the selected heliostat at equinox (21.3.) compared to the most optimistic case: the ideal MMA with antireflective coating. Although the MMA performance comes close to that of the reference heliostat at noon, it drops off much more at lower sun positions. As mentioned before, the main reason for this behaviour is the cosine loss.

|

Table 1. The MMA in the ideal configuration with antireflective coating shows a slightly lower performance

than the reference heliostat (about -5%). The greatest loss of reflection efficiency is due to the light twice pass-

ing through the cover glazing resulting in reflection and absorption losses. For the ideal MMA without antire-

flective coating, these effects are even more pronounced and make the MMA efficiency drop by about 13%.

Further, in the realistic case the reduced area of the mirror facets allows a significant amount of radiation to

pass between and outside of the facets, thus reducing the overall efficiency by about 18%, compared to the ref-

erence heliostat.

|

Figure 8: Performance of all configurations (21.3. 12:00)

Figure 9: Annual performance of all configurations

If the performance is evaluated on an annual basis, the MMA losses are significantly higher than that of the reference heliostat.

Figure 9 shows the annual performance of all cases. The difference to the previous situation is mainly the increase in cosine losses. The projected area of the MMA is affected by the fact that the position of the box is fixed, and the incidence angles of the solar radiation cover a wide range. In contrast, a conventional heliostat is always tracked in such a way that the mirror normally points midway between the

sun vector and the vector towards the receiver, i. e. the projected area is greater. The detailed results are given in table 2.

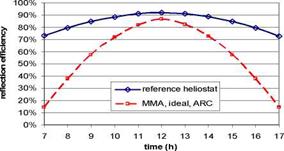

This characteristic is much more obvious when looking at the performance over a day.

Figure 10 shows the daily performance for the selected heliostat at equinox (21.3.) compared to the most optimistic case: the ideal MMA with antireflective coating. Although the MMA performance comes close to that of the reference heliostat at noon, it drops off much more at lower sun positions. As mentioned before, the main reason for this behaviour is the cosine loss.

|

Table 1: Performance results for 21.3. 12:00

|

Since the MMA’s can be installed beside one another without shading their neighbours, the MMA system allows a denser packing of the heliostat field. Due to their movement, conventional heliostats need a minimum spacing between them to achieve low shading. However, usual heliostat field layouts are optimized taking this effect into account, and the resulting shading losses are normally quite low. Nevertheless, the land use factor is better with a MMA type heliostat. Further analysis is required to find out how complete MMA heliostat fields perform, compared to conventional heliostat fields.

|

Figure 10: Daily performance of the MMA and the reference heliostat |

The discussed mini-mirror array promises a low-cost heliostat design. A first demonstrator unit with a reduced size has been developed and built with high-quality materials. The present unit uses conventional step-motor drives and ball and socket joints. However, the low-cost potential is counterbalanced by approximately 30% less optical performance compared to conventional heliostat designs, mainly due to increased cosine losses. In the next step of the current project the performance of the test unit will be analysed in detail with the artificial sun of the SIJ and an ecobalance will be worked out. In further studies the heliostat field performance and the cost reduction options shall be carried out.

The project is funded by the German Ministry for the Environment, Nature Conservation and Nuclear Safety under contracts 03UM0074 and 03UM0075.

References

[1] F. Krawiec, J. Thornton, M. Edesess, 1980, An Investigation of Learning and Experience Curves, SERI, Golden, Colorado, Contract No. EG 77 C 01 4042

[2] G. J. Kolb, S. A. Jones, M. W. Donnelly, D. Gorman, R. Thomas, R. Davenport, and R. Lumia, 2007, Heliostat Cost Reduction Study, Sandia Report SAND-2007 3293, Sandia National Laboratories, Albuquerque

[3] C. L. Mavis, 1989, A Description and Assessment of Heliostat Technology, Sandia Report SAND87- 8025, Sandia National Laboratories, Albuquerque[4] R. Buck, E. Teufel, 2008, A Comparison and Optimization of Heliostat Canting Methods, J. Solar Energy Engineering 2008 (accepted for publication)

[5] F. Ansorge, J. Wolter, H. Hanisch, B. Hoffschmidt, M. Reindl, Device for Concentrating Light, Particularly Sunlight, International Patent WO 2006/005303 A1, 19.1.2006