Economic Analysis

The solar assisted heat pump desalination system, which has been constructed, is an experimental setup, thus it produces a small amount of desalinated water. In order to make it economically feasible, it is necessary to scale up the system into a higher production capacity, one that is able to provide water for domestic needs, or to supply water in remote areas. From Table 1, we can see that to supply the water requirement for a single family we need to produce at least more than 150 l of water per day. With a production rate of 150 //day, the system will also be able to supply

potable water to a remote elementary school of 60 students. However, we must always take into account the amount of investment needed and the payback period of the system to make it economically feasible.

|

Table 1 Water requirement of commercial and institutional buildings [9]

|

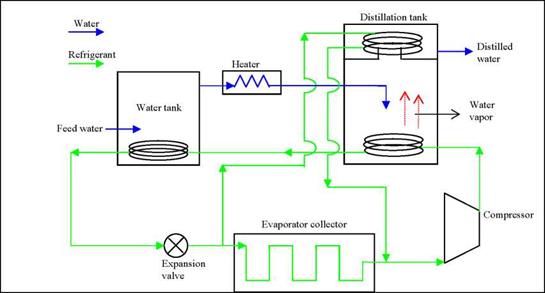

A high price of solar liquid collector will cause the solar energy savings to be less competitive compared to conventional fuel systems. Therefore, it is necessary to make use of the heating and cooling provided by the heat pump efficiently. In order to achieve this, a new setup is proposed as shown in Figure 7. In the new setup, the refrigerant is allowed to condense fully through the distillation chamber and water tank, thus heating the feed water. Therefore, the need of liquid solar collector to preheat the feed water may be eliminated from the system. In the proposed new design, the distillation chamber will maintain the same vacuum pressure of 0.14 bar, thus water saturation temperature will still be at 52 °C. Refrigerant leaving the desalination chamber will preheat the feed water close to a temperature of 50 °C and feed water will be further heated by the electrical heater to 70 °C.

|

Figure 7: Proposed solar heat pump desalination setup |

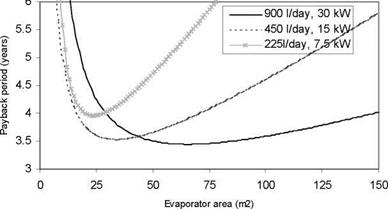

The proposed setup produces distillate water at different production rates, and thus different component sizes and investments are needed. A comparison of the production rates, 225 //day, 450 //day, and 900 //day showed that at lower production rate, the payback period increases. At low production rate, as shown in Figure 8, less solar energy is used in the process, thus the fuel savings is reduced, resulting in higher payback period. At 225 //day the payback period is close to 4 years, while at 450 and 900 //day the optimum payback period close to 3.5 years. At 900 //day, the operation and maintenance cost of the system is high, thus reducing the savings acquired from solar energy usage, causing a similar payback period to 450 //day. At 225 l/day the optimum collector area is 20 m2, while for 450 and 900 l/day it is 34 and 67 m2, respectively. For production of 450 // day, it is achieved with a compressor power input of 15 kW, and 30 kW for 900 // day.

|

Figure 8: Comparison of payback period for different production rates |

|

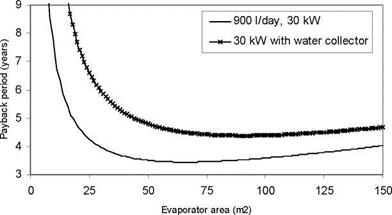

Figure 9: Comparison of payback period with the usage of liquid solar collector |

As shown in Figure 9, installation of solar water collector to the system with a production rate of 900 //day will increase its optimum payback period to more than 4 years. A system with the same production rate will have a lower payback period without utilizing the solar water collector.

6. Conclusions

A series of experiments has been conducted with the solar assisted heat pump desalination system. A liquid solar collector was added to the system to preheat the feed water before entering the distillation chamber. Experimental results showed that the system could reach a Coefficient of Performance (COP) of 10, and at a relatively stable meteorological conditions, the evaporator collector has an efficiency value between 80 and 90%, whereas the liquid solar collector has an

efficiency value between 50 and 60%. The water production rate is generally close to 1 l/hr for the system, with a Performance Ratio (PR) close to 1.5.

An economic analysis was conducted to determine the feasibility of the system. It was found out that in order to be feasible, the system’s production capacity must be increased. However, the increase of production rate will also increase the investment cost of the system. With the high price of liquid solar collector, the payback period of the system becomes less feasible. A new design of the system, one that does not use liquid solar collector, was proposed. With the new design, the payback period of the system becomes much more attractive. A high production rate will require more investment cost, and it is shown that removing the liquid solar collector will reduce the payback period significantly. The optimum payback period of the system with a 900 l/day production is close to 3.5 years with a 67 m2 evaporator collector. Analysis of the economic parameters showed that the oil price is very influential in determining the competitiveness of the system.

In conclusion, it was found that the solar assisted heat pump desalination system exhibits great potential for future developments. With the increase of oil fuel prices, solar energy will likely to be more economically feasible as a source of clean energy.

Nomenclature:

I Solar irradiation, W/m2

|

|

AC Collector area, m2

[1] Renato Lazzarin (2001), Ground as a possible heat pump source, Geothermische Energie, 32/33, 9, http://www. geothermie. de/gte/gte32-33/gte32-33index. htm

[2] T. N. Anderson, G. L. Morrison, M. Behnia (2002), Experimental analysis of a solar-boosted heat pump water heater with integral condenser, Proceedings of Solar 2002, Australian New Zealand Solar Energy Society

[3] J. Siqueiros & F. A. Holland (2000), Water desalination using heat pumps, Energy, 25, 717-729

[4] Onder Ozgener, Arif Hepbasli, A review on the energy and exergy analysis of solar assisted heat pump systems, Renewable & Sustainable Energy Review, 2005, pp.1-16

[5] Torres Reyes E, Cervantes de Gortari J., Optimal performance of an irreversible solar-assisted heat pump, Energy Internal Journal, 1(2), 2001, pp.107-111

[6] Hawlader, M. N.A., K. C. Ng, T. T. Chandratilleke, D. Sharma and Kelvin Koay H. L., 1987, Economic Evaluation of A Solar Water Heating System. Energy Conversion Management, vol. 27, pp 197 - 204

[7] Kreider, Jan F., Charles J. Hoogendoorn, and Frank Keith, 1989, Solar Design: Components, Systems, Economics, Hemisphere Publishing Corporation

[8] Hawlader, M. N.A., Prasanta K. Dey, Sufyan Diab and Chan Ying Chung, 2004, Solar Assisted Heat Pump Desalination. Desalination, vol. 168, pp 49 - 54

[9] Stein, Benjamin, John S. Reynolds, and William J. McGuinness, 1986, Mechanical and Electrical Equipment for Buildings 7th Edition, John Wiley and Sons