New developments in advanced welding

Advances in GMAW technologies

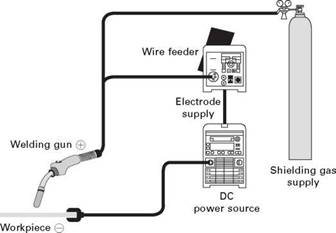

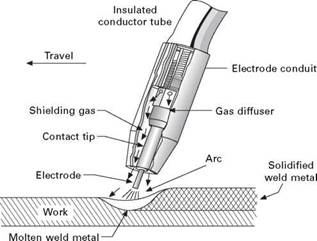

Traditional power sources for GMAW welding are the analogue constant voltage (CV) type, with the welding current setting controlled by the wire electrode feeding rate (Nadzam, 2003). A schematic of a typical DC power source, with the welding torch connected to the positive electrode or DC+ or DCRP is shown in Fig. 1.1. As a reminder, the fundamentals of the GMAW process are presented schematically in Fig. 1.2, showing the electric arc, gas shielding, wire electrode and weld deposit.

|

Shielding gas regulator

1.1 Schematic view of a GMAW welding system showing main components (Himmelbauer, 2003). |

|

1.2 Schematic representation of the GMAW process in a longitudinal cross-section (Nadzam, 2003). |

|

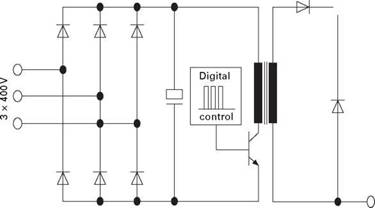

1.3 Schematic representation of electrical components of a typical GMAW digital power source and control system (Himmelbauer, 2003). |

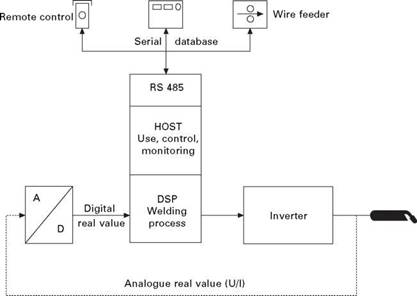

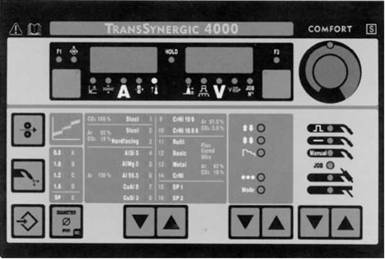

One major development in improving the efficiency of the transformer introduced in the 1980s was in using high frequencies to reduce thermal energy losses via eddy current heating of the transformer core, thus reducing the size of the transformers. The current in the secondary was then lowered again for welding and this ‘inverter’ technology was used to make GMAW power sources more portable (Fig. 1.3, Himmelbauer, 2003). Furthermore, as digital control technology improved, pulsed GMAW (GMAW-P) power sources were developed, with a block representation shown in Fig. 1.4. With these digital power sources several improvements were accomplished besides better process control and reproducibility: the ability to programme and monitor the waveform, remote access and single-knob (‘synergic’) adjustment with the control panel shown in Fig. 1.5 (Courtesy Fronius International). Using this control, sets of pre-programmed welding parameters are called out from a large database, eliminating the trial and error set-up typical of semi-automatic operations.

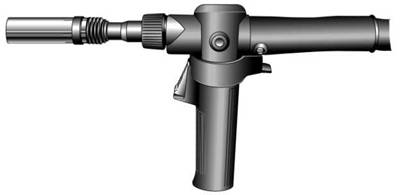

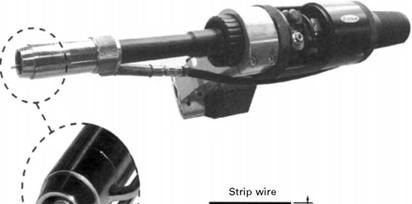

Different wire electrode types can have specific problems with feeding in ‘push’ and ‘push-pull’ modes. Mathematical modelling and experiments recently showed that the friction force between the wire and its liner resisting feeding increases exponentially with the liner bend angle (Padilla et al., 2003). To reduce this friction force, a typical push-pull torch is shown in Fig. 1.6, while another solution to this feeding problem is to use small spools attached to the torch (Fig. 1.7), (Nadzam, 2003).

Contact tube life can be extended by understanding better the thermal deterioration process governing its wear. It was found that the radiant heat of

|

Control panel

|

1.4 Block diagram of a modern inverter-type power supply (Himmelbauer, 2003).

|

|

1.5 View of a 'single-knob' control panel for a typical synergic GMAW system (Himmelbauer, 2003) (Courtesy Fronius International).

|

1.6 View of a typical 'push-pull' GMAW welding gun that incorporates an extra wire feeding motor in the handle. |

|

1.7 GMAW welding pull-type gun having a small diameter wire spool attached to the gun (Nadzam, 2003). |

the arc plasma and resistive heating at the electrode-wire interface are mostly responsible for heating the contact tip (Adam et al., 2001). Thus the contact tip to work distance CTWD (Fig. 1.8) had the most important effect on the tip overheating, while arc-on time also played a major role on contact tip temperature. The lower the CTWD, the more overheating the electrode tip experienced, confirming the major role of heat radiation from the arc on the contact tip temperature and consequent wear.

Traditionally, solid cylindrical wires have increasingly been replaced by tubular electrodes, i. e. metal-core or flux-core (Myers, 2001). The main advantage of these cored wires lies both in their containing a mix of alloying

elements and in their flexibility for tailoring weld deposit properties. Metal core (MC) wires have been used to weld high performance weathering steels with 70 and 100ksi (490 and 700 MPa) yield strengths and excellent toughness at no preheating in 50.8 mm (2 inch) thick plates. Use of large diameter solid wires of up to 3.2mm (0.125 inch) in diameter resulted in increased deposition rates at equal power (Himmelbauer, 2003). Another development is in use of strip wires of 0.5 x 4.5 mm rectangular cross-section instead of cylindrical ones (Himmelbauer, 2003). One major advantage of using these strip wires is in higher wire feed speeds up to 11 m/min and therefore the high deposition rate by using a push-pull system (Fig. 1.9). Penetration was lower when compared with round cross-sections of equivalent area, but strip wires can therefore easily be used for weld surfacing. One major disadvantage of strip wires lies in attempting to feed them in twisted liners typical of robotic and complex semi-automatic motions.

Two major types of shielding gases are being used in GMA welding: (1) inert and (2) active or reactive. European standards designate the two subsections of GMAW as MIG (metal inert gas) vs. MAG (metal active gas) welding. Binary and ternary gas mixes have been developed in order to optimise the chemical activity, ionization potential and thermal conductivity combination (Vaidya, 2001; Zavodny, 2001). Application of these custom-made gas mixes also have to be co-ordinated with the droplet transfer modes used (Nadzam, 2003). Care has to be exercised when using Ar + CO2 mixtures in welding

|

|

|

1.9 Rectangular strip wires used with 'push-pull' feeding systems (Himmelbauer, 2003). |

stainless steels, as detrimental carbon pickup can occur (Kotecki, 2001). There can be an adverse effect of metal transfer mode on the weld carbon contamination; the worst is the spray mode for a given CO2 content in the shielding gas.