Handbook of Cellulosic Ethanol

Liquid Biofuels

Liquid biofuels fall into three general categories:

1. Bioalcohols

2. Vegetable oil - and algae-based biodiesel

3. Biomass-based hydrocarbon fuels or drop-in biofuels

The most commonly used liquid biofuels are bioethanol and biodiesel. Currently, bioethanol is produced primarily from corn and sugarcane. Biodiesel is made from virgin plant oils such as soybean oil, rapeseed oil, palm oil, and from algae. The amount of plant oil that can be harvested from these crops varies widely; some of the common crops under consideration for vegetable oil-based biodiesel, and oil yields per hectare, are shown in Table 1.1 [14].

|

Table 1.1 Typical vegetable oil yields from the various biomasses [14].

|

In addition to this, used cooking oil and animal fats like chicken fat can also be used in the synthesis of biodiesel. Liquid biofuels have made a small but growing contribution to transport fuel usage worldwide, currently providing about 3% of global road transport fuels [2].

These fuels are mainly used in ground transportation systems as blends with conventional fuels. A limited amount of biofuel is used by the marine transport sector, and interest is growing in the use of biofuels for aviation. Camelina-, Jatropha-, and algae - based bio oils are of primary interest in renewable aviation fuel research. Liquid biofuels derived from these oils have been tested as blend-in fuels with jet kerosene in commercial and demonstration flights. Ethanol is by far the most popular liquid biofuel and a comparison of biodiesel and bioethanol in primary feedstocks and production costs in different parts of the world are shown in Table 1.2.

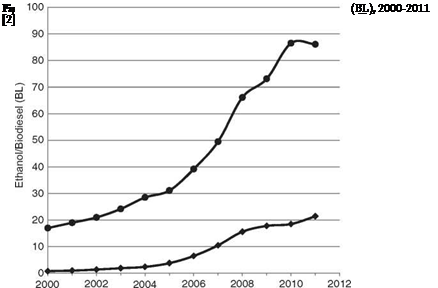

Bioethanol and biodiesel are the two major liquid biofuels. There has been a gradual increase in the production of these fuels; global ethanol and biodiesel production in billon liters (BL) from 2000-2011

|

Table 1.2 Estimated production costs (US $/Liter) of first generation renewable transportation fuels.

Notes: Costs are indicative of economic costs, levelized, and exclusive of subsidies or policy incentives [2]. |

|

is shown in Figure 1.3. Bioethanol production has increased from 17 BL in 2000 to 86 BL in 2011, whereas biodiesel has increased from

0. 8 to 21.4 BL during the same period [2]. Global production of fuel ethanol was down slightly in 2011, from 86.5 BL in 2010 to 86.1 BL in 2011. In 2011, the United States and Brazil accounted for 64% and 25% of global ethanol production, respectively, compared with 60% and 30% in 2010. Although global production was slightly down, in the United States bioethanol production reached a new high, exceeding 54 billion liters in 2011 [2].

Brazil is the second largest fuel-grade ethanol producer in the world. Together, Brazil and the United States lead the industrial production of ethanol fuel, accounting for 88.8% of the world's production in 2011. In 2011, Brazil produced 21.1 billion liters representing 24.9 percent of the world's total ethanol used as fuel. However, fuel ethanol production in Brazil has declined recently due to several reasons like financial crisis, poor sugarcane harvests due to unfavorable weather and high world sugar prices. China is the world's third largest ethanol producer with a production capacity of 2.1 billion liters in 2011, and is the largest ethanol producer in Asia. On a global scale. China is followed by Canada (1.8 billion liters), France (1.1 billion), and Germany (0.8 billion).

In contrast to ethanol, global biodiesel production continued to expand, increasing by almost 16% to 21.4 billion liters in 2011, compared with 18.5 billion liters in 2010. The United States saw a record year, with biodiesel production increasing by 159% to nearly 3.2 billion liters, mainly from soybeans. As a result, the United States surpassed the 2010 leaders Germany, Brazil, Argentina, and France, to become the world's top producer. The dramatic increase in biodiesel production in the United States was due to a government mandate in mid 2010 that required refiners to blend 3.1 billion liters (800 million gallons) of biodiesel with diesel fuel in 2011 or face stiff daily fines. The EU remained the largest regional producer of biodiesel, but its total production declined by 6%, and the EU share of the world total was down from 53% in 2010 to 43% in 2011. Germany dropped from first to second place globally in biodiesel production, although its production increased by 18%. The other major biodiesel producers in 2011 were Argentina (2.8 billion liters), Brazil (2.7 billion liters), and France (1.6 billion liters).

Vegetable oils are unsatisfactory for direct use as fuel in an engine due to the higher level of viscosity, lower volatility, free fatty acid content and the matter of carbon deposits. These deficiencies considerably limit the use of raw oil as a direct substitute for diesel fuel [15]. Many technologies and methods have been tested to reduce the viscosity of raw vegetable oil. These include pyrolysis, catalytic cracking and trans-esterification with small alcohols like methanol or ethanol. Biodiesel blended or used to replace diesel is produced by trans-esterification of vegetable oil or waste fats, hence biodiesel can be defined as mono alkyl esters of fatty acids derived from vegetable oil or animal fats. Among many techniques, trans-esterification with methanol using sodium hydroxide as the catalyst is the most promising method for conversion of vegetable oils or waste fats to biodiesel. The reaction is normally carried out with a sequence of three consecutive reversible reactions [16]. In this process triglyceride is converted stepwise into diglyceride, monoglyceride, and finally to glycerol in which one mole of alkyl ester is formed in each step [17].

A number of researchers have discussed the advantages of biodiesel such as heat content, ready availability; also some disadvantages such as high viscosity, lower volatility, and the reactivity of unsaturated hydrocarbon chains [18-20]. Shahid and Jamal [21] have reviewed a wide range of vegetable oils such as sunflower oil, cottonseed oil, rapeseed oil, soybean oil, palm oil, and peanut oil for their usefulness in biodiesel production and blending biodiesel with petroleum diesel. They concluded that using a mixture of petroleum diesel and biodiesel at an 80:20 ratio (B20) was the most successful.