Experimental setup

The experiments are carried out in a domestic hot water tank and a space heating tank. Both tanks are of steel and have a volume of 400 litres with an internal height of 1.4 metres.

In the domestic hot water tank, fresh domestic water with high natural lime content, usual for Danish conditions, is led into the tank during cooling of the tank. During heating the water is circulated from the bottom of the tank through an external heat exchanger where it is heated and then led into the fabric pipe through the bottom of the tank. In this way domestic hot water is led into the fabric stratifier through the bottom of the tank. The inner surfaces of the domestic hot water tank are enamelled.

In the space heating tank, the same “dead” water is circulated. During heating the water is circulated from the bottom of the tank through an external heat exchanger where it is heated and then led into the fabric pipe through the bottom of the tank. In this way “dead” water is led into the fabric stratifier through the bottom of the tank. The inner surfaces of the space heating tank are not enamelled, no anode preventing corrosion is used and no additives preventing algae growth are added to the water.

|

Fig. 1. The space heating tank (left) and the domestic hot water tank (right) used for the accelerated durability tests of the fabric inlet stratification pipes. In the front of the picture, a 27 kW heating element and two plate heat exchangers used for heating the water that circulates through the inlet stratifiers can be seen. |

|

The fabric inlet stratifiers consist of two concentric fabric pipes, with diameters of 40 mm and 70 mm and the pipes are closed at the top. The pipes are mounted in a circle as shown in Fig. 2. The fabric inlet stratification pipes are secured at the cap in the bottom of the tanks, which is the only opening in the tank and spread over 93% of the tank height. Heating tests where cold tanks are heated with hot water through one fabric stratifier at the time, then cooled down again/heated again and so on are carried out during the test period. Tank temperatures, inlet and outlet temperatures and the volume flow rate through the inlet stratification pipes are measured during the whole test period.

The results of the investigations show that several of the tested fabric pipes build up thermal stratification in exactly the same way after being in operation for a long time in the space heating tank. The investigations also show that this is not the case with any of the fabric pipes in the domestic hot water tank.

Table 2 shows the investigated fabric styles and the main results. Most likely there is a problem with deposits of lime attached to all pipes in the domestic hot water tank resulting in a strongly decreased ability to build up thermal stratification for all the fabric pipes tested.

For the space heating tank with “dead” water five of the tested fabric inlet stratifiers work at the end of the test period without decreased ability to build up thermal stratification, while two fabric inlet stratifiers have decreased ability to build up thermal stratification.

In order to eliminate small differences in the start temperature and inlet temperature from one experiment to the next in tests conducted with the same operation conditions, the normalized temperatures are used when comparing the thermal stratification profiles in the following figures. The normalized temperature is defined as:

(T - Ttank, start)/(Tinlet-Ttank, start ) (1)

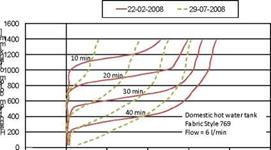

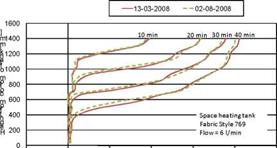

In Fig. 3 - Fig. 5 normalized temperatures as functions of the height in the tanks obtained during heating periods are shown in the middle and at the end of the test period. For example, the heating curves for the fabric inlet stratification pipes style 769, 700-12 and 981 are shown for tests with a volume flow rate of 6 l/min, inlet temperatures of 44°C - 46°C over a time period of five months.

|

|

Curves after 10, 20, 30 and 40 minutes of heating are shown. From the figures it is clear that capability to build up thermal stratification is strongly decreased in the domestic hot water tank during the five-month period for the three shown fabric pipes. For the fabric pipes in the space heating tank, the capability of building up thermal stratification is slightly decreased for the fabric pipe style 981 while the capability of building up thermal stratification for the fabric pipes style 769 and 700-12 is unchanged during the five month-period.

|

Table 2. The tested fabric styles and main results.

|

-0.2 0 0.2 0.4 0.6 0.8 1 -0.2 0 0.2 0.4 0.6 0.8 1

(T_Ttank, start)/(TinleirTtank, start) [-] (T-T tank, start)/(TmlefTtank, start) [-]

Fig. 3. Temperature profiles for heating tests with the fabric inlet stratification pipe style 769 in the domestic

hot water tank (left) and the space heating tank (right). The volume flow rate is 6 l/min.

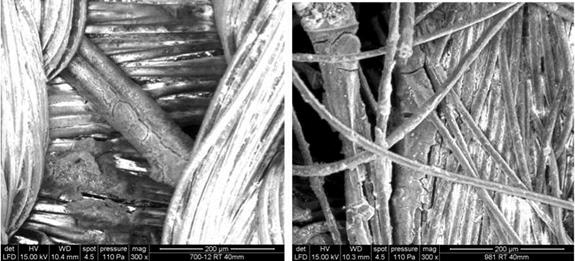

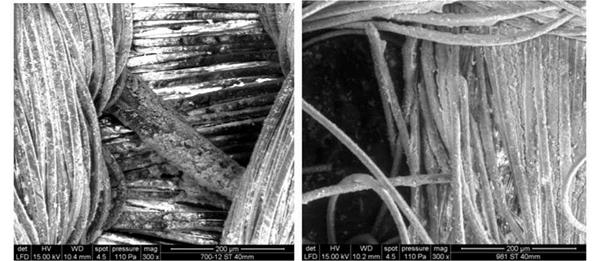

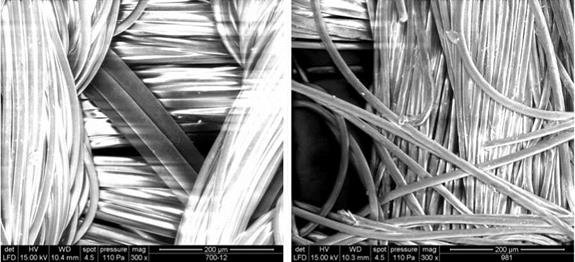

Fig. 6 shows the fresh fabric styles 700-12 (left) and 981 (right) before the tests. Fig. 7 and Fig. 8 show the fabric styles after the test period in the domestic hot water tank and in the space heating tank, respectively. The pictures are of the inside of the top of the inner fabrics. The fabric style 700-12 is a knit fabric with a dense structure while fabric style 981 is a woven fabric with relatively large holes in the structure. All the dark areas in the pictures are holes in the fabric structure. The pictures in Fig. 7 clearly show the lime deposits along the fabric fibres on both fabric styles. The pictures in Fig. 8 show smaller fractions of deposits, presumably from dirt and algae.

In the pictures, it can be clearly seen, that the fabrics are still permeable after the tests, especially the fabric style 981. However, deposits may result in stiffness of the fabric and hence prevent the fabric from contracting in order to equalize the pressure difference between the fabric pipe and the water in the tank in levels where the temperature in the pipe is higher than the temperature in the tank. This will result in the fabric starting to behave as a rigid pipe with holes where the pressure causes water to enter the fabric pipe at lower levels and thereby reducing the temperature in the pipe. Such a pipe is a mixing device rather than a stratification device [4].

|

|

|

|

|

In order to quantify the mass of the deposits attached to the fabric pipes, the pipes were taken out of the tanks and weighted. Figure 9 shows the gained weight of each fabric pipe.

|

|

|

|

|

|

|

The long time durability of seven different fabric inlet stratification pipes is investigated experimentally in a domestic hot water tank and in a space heating tank. The results show that the lime contained in the domestic water is deposited in the fabric pipes in the domestic hot water tank and that this destroys the capability of building up thermal stratification for the fabric pipe. The results also show that although dirt, algae etc. are deposited in the fabric pipe in the space heating tank, the capability of the fabric inlet stratifiers to build up thermal stratification is unchanged for five of the seven fabric pipes within an operation period corresponding to operation of a solar heating system with a solar collector area of 10 m2 with a volume flow rate of 0.2 l/min per m2 solar collector area in 2/3 year.

Most likely the deposits result in rigid inflexible pipes while dirt and algae deposits, at least for a long period, do not destroy the flexibility of the fabric pipes.

The investigations have also shown that there is a need for further research on:

• Durability tests for much longer period of time of fabric inlet stratification pipes in a space heating tank

• The influence on the amount of deposits of dirt, algae etc. in the fabric pipe by adding e. g. an anode for corrosion protection and additives to prevent algae growth in the space heating tank used for the durability tests

• The durability of fabric inlet stratification pipes at high temperatures (90-95°C)

• How the mounting of the fabric inlet stratification pipe influences the capability of building up thermal stratification

Nomenclature

T Measured temperature in the tank during the experiment [°C]

Ttank, start Measured temperature in the tank at the beginning of the experiment [°C]

Tinlet Measured inlet temperature [°C]

References

[1] E. Andersen, S. Furbo, J. Fan, (2007). Multilayer fabric stratification pipes for solar tanks, Solar Energy, Vol. 81, pp. 1219-1226.

[2] E. Andersen, S. Furbo, M. Hampel, W. Heidemann, H. Muller-Steinhagen, (2007). Investigations on stratification devices for hot water heat stores, International Journal of Energy Research, May 2007.

[3] E. Andersen, S. Furbo, (2006). Fabric inlet stratifiers for solar tanks with different volume flow rates, in proceedings of EuroSun 2006 Congress, Glasgow, Scotland

[4] L. J Shah, E. Andersen, S. Furbo, (2005). Theoretical and experimental investigations of inlet stratifiers for solar storage tanks. Applied Thermal Engineering 25, pp. 2086-2099.