Geometry optimisation

The starting point for the design of the concentrator geometry was the concept of the Fixed Mirror Solar Concentrator (FMSC) that is illustrated in Figure 1. Although the first development was

|

already carried out during the 70's by the General Atomic Company [3], at present no commercially available collectors use this concept.

A complete analysis of the reflector optics, based on the forward ray tracing method, was carried out [4]. The main parameters taken into account in that study were the geometric concentration factor and the D/W ratio (see Fig. 1). On the one hand, this study together with the results already available on the literature [5, 6, 7] show that working temperatures of 200°C and higher could be easily obtained and that the radiation distribution in the focus is quite uniform (compared to other geometries). On the other hand, the concentration factor depends on the number of steps (or flat mirrors), which complicates manufacturing with the required precision, and the sealing of the mirror edges. Another problem of this geometry was that for low transversal sun angles the interference of the reflected rays with the adjacent mirrors produces high energy losses.

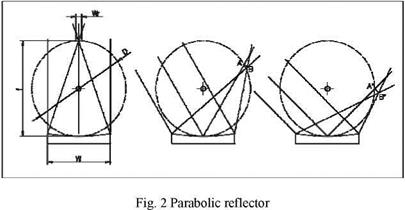

Therefore it was decided to investigate the possibility of reducing the number of the required steps by using curved mirrors. Although it is well known that a parabolic reflector only produces a point focus for normal incidence, it can be shown from simple geometric considerations, that its degraded focus describes a circular path similar to the FMSC [8]. Thus the parabolic curve was chosen as the main candidate for the curvature of each of the mirrors.

|

From the same study [8] it was clear that for low geometrical concentration factors the best solution consisted in replacing the stepped geometry by only one parabolic reflector (Figure 2). Therefore a more detailed optical analysis of this geometry was performed [9].

The optical studies were complemented with a simple thermal analysis at 120°C [8]. The figure 3 shows the annual averaged efficiency estimations, referred to the global radiation incident on the reflector aperture, using available Mallorca’s radiation data and the TRNSYS climate processor.

|

As can be seen, the best annual averaged efficiency is obtained for the single mirror arrangement and a concentration factor between 10 and 12. The figure 3 was obtained for a D/W ratio of 1.5. The precise value of the optimal concentration ratios and the estimated efficiencies depend on the D/W ratio assumed, but in all cases of practical interest the best results were obtained for the single mirror reflector.

|

Regarding to the D/W ratio, for ideal reflectors it is clear that the efficiency increases with increasing D/W values. Nevertheless, in practical implementations, its value is limited to values below 2 due to both the dispersion produced by the mirrors and the precision of the tracking mechanism. In the first prototype the chosen value was 1.5.

The figure 4 shows the estimated incidence angle modifiers (IAM) for the chosen geometry, taking also into account the finite length of the collector and the interference between adjacent receivers.